What is the difference between BS 8524-1 and BS 8524-2 in terms of the certification schemes that underpin the two standards?

What is the difference between BS 8524-1 and BS 8524-2 in terms of the certification schemes that underpin the two standards?

The third-party certification of BS 8524-1 and 8524-2 appears to be causing some confusion with some contractors and design teams. BS 8524-1 consists, (in our case) of 18 distinct physical product tests, including specific fire and spread of flame tests, impact testing, elevated motor testing, ancillary tests, and smoke leakage tests that we carried out with Warrington Fire. We then took the entire testing programme with its distinct test reports and applied for a third-party accreditation through IFC (International Fire Consultants) to cover BS 8524-1 in its entirety. BS 8524-1 falls under IFC’s SDP11-02 scheme. Our certificate looks like the below and is referenced number IFCC 1542. It is certainly worthwhile mentioning that the IFC 3rd party scheme to BS 8524-1 appears to be the only scheme acceptable to the majority of UK building controls for the manufacture of fire curtains.

BS 8524-2 is the practice of application, installation, commissioning, and maintenance. There is no physical fire or other testing involved. (To reiterate, that takes place in part BS 8524-1.) There is no specific scheme that relates to BS 8524-2 only. Instead, the IFC SDI 05 scheme is an umbrella scheme under which all of the following 5 types of products fall, including BS 8524. As a note, Warrington Fire through their FIRAS installer scheme do not currently offer 3rd party certification to BS 8524-2, so unsurprisingly the IFC third party certification scheme for installation, commissioning and servicing to BS 8524-2 is the only scheme that UK building control appear to accept. IFC document the following,

“The IFCC (IFC Certification), ‘Installation, commissioning and servicing of Fire and Smoke Barrier Assemblies (SDI 05) allows registered installation, commissioning and servicing companies to certificate specific projects in respect of the efficacy of the installed product to restrict and contain the spread of smoke in compliance with objectives of a SHEV (smoke and heat exhaust ventilation system) as defined in accordance with BS EN 12101- 1:2005+A1:2006 and to ensure that it remains effective throughout its life expectancy, or to restrict the spread of fire in compliance with the objectives of fire compartmentation.”

There are a number of fabric fire and smoke barriers and these can be identified by their type/function as follows:

Type 1: Active fire curtain barriers in compliance with BS 8524-1,-2:2013

Type 2: Fixed fire barriers satisfying the test criteria of BS476-22:1987 or

BS EN 1364-1:2014+A1:2018. Fire barriers are covered in separate IFCC Scheme Documents ‘Installing Fire Stopping Systems’ (SDI 09) and’ Installing cavity barriers’ (SDI 10). In circumstances where a fixed smoke barrier is required for smoke control in a building, these would be covered by the scope of this document.

Type 3: Active fire barriers satisfying the test criteria of BS 476-22:1987 or BS EN 1634-1:2014+A1:2018

Type 4: Active smoke control curtain barriers in compliance with the requirements of BS476-31.1:1983, or BS EN 1634-3:2004

Type 5: Active smoke control barriers in compliance with BS EN 12101- 1:2005+A1:2006

The certification looks like the below and our reference is IFCC 3425. It covers all five types of fire and smoke barriers including BS 8524 and is awarded following comprehensive office, systems, installation and maintenance auditing by IFC.

Details of third-party certified companies are hosted on IFC’s website.

For any questions about the A1S Group Flameshield 8524 fire curtain range, please contact:

info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

A1S Group Delighted to win Four Landmark Projects

In terms of iconic projects, we really are spoilt for choice this month with what is further recognition for our Flameshield fire shutter and fire curtain range.

In terms of iconic projects, we really are spoilt for choice this month with what is further recognition for our Flameshield fire shutter and fire curtain range. We had highlighted London Selfridges’ refurbishment, Edinburgh’s new John Lewis development, the stunning new (subject to NDA) Museum in Stratford and of course the majestic Katara Towers in Doha and hoped to win at least one of the projects.

Paul Caldwell-Jones, A1S Group Head of Sales and Marketing said, “To win all four projects is testament to A1’s growing reputation as a world leading fire shutter and fire curtain manufacturer and installer.“

A1S Group Export Manager Mark Dougill was particularly fulsome in his praise for Al Thuraya our Qatari partners who initially secured the Doha fire shutter package. “The Katara Towers will undoubtedly become one of the world’s most iconic structures,“ he said, “I am delighted to see our Flameshield shutters installed as a pivotal part of the fire strategy.” The imposing structure is an architectural translation of Qatar’s national seal representing traditional scimitar swords.

Flameshield fire shutters, in particular Flameshield FS240 JMs are to be manufactured and installed as part of the fire strategy for the John Lewis £20 million fit out in Edinburgh and Flameshield EW120 fire curtains are required for the (subject to NDA) Museum in London. This product retains the highest radiation performance for a UK fire curtain and is C1 class tested which is why it was selected by the design team at MCLH.

A1S Group Engineered Fire Curtains in the Science Museum

Kensington’s world-famous Science Museum houses more than 300000 objects over seven floors.

Kensington’s world-famous Science Museum houses more than 300000 objects over seven floors. To John Logie Baird’s test subject “Stookie Bill”, the Apollo 10 command module, Charles Babbage’s Difference Engine No 1, Crick and Watson’s DNA model and the first Apple computer, you can now add an A1S Group Flameshield BS 8524 fire curtain. So, congratulations to all the team at A1S, our engineered life critical fire safety equipment has now joined the pantheon of global science history.

On reflection, maybe we are getting a little bit ahead of ourselves. As it turns out that the Flameshield 120 minute integrity curtains aren’t exhibits after all. Following a competitive and detailed compliance process, they were chosen to form a pivotal role in the fire strategy for the museum’s state of the art IMAX cinema. Another great win for the A1S UK fire curtain supply and installation team, backing up our mantra, always compliant, always competitive.

Some Common Sense Guidance For Fire and Smoke Curtain Procurement

Better Safe than Sorry – some common-sense suggestions to cut through the smog of fire and smoke curtain procurement and guidance to avoid expensive and hazardous procurement pitfalls.

Better Safe than Sorry – some common-sense suggestions to cut through the smog of fire and smoke curtain procurement and guidance to avoid expensive and hazardous mistakes.

It’s always great to talk to clients, but in response to the same questions and scenarios coming up time and time again, it is worth hosting a few words on the dos and don’ts of fire curtain procurement, based on our experience as manufacturers and installers of fire and smoke curtains.

I am getting more and more feedback, especially on Design and Build contracts from Tier One Commercial Managers and Quantity Surveyors, that they haven’t budgeted enough, (despite our package being the most competitive) for the product and install package because their estimating team did not understand the permutations of products and British Standard options available and hadn’t understood the governing design of the fire strategy and curtain specification. Estimators are going to market and capturing costs that can sometimes increase dramatically because the products quoted are not in line with the building’s fire strategy. Absolutely no blame there. Fire and smoke curtains are notoriously difficult to get right. Often there are clues within a fire strategy, that unless you are used to them can trip you up. In our experience, a fire and smoke specification does not always align exactly with the fire strategy. There are often ambiguities and inconsistencies that require clarification and in every case before we price any project, we make sure that what is being quoted is going to be signed off by building control.

In recent months, the issue has become almost endemic and we are increasingly being asked to replace recently installed fire curtains from other manufacturers and installers as they did not meet ALL of the specification/British Standard testing requirements. For those who already know this then forgive the statement, but there are potentially hundreds of combinations of British Standard, functionality, integrity, radiation, ancillary, third party accreditation, parameters and related requirements that could be required for your project. Even worse than under-budgeting is if you get this wrong, you as a contractor could well be replacing your recently installed fire curtains, dismantling and rebuilding structures, delaying practical completion and warring with your end client on the legalities of catch all clauses such as “all current and relevant standards” in your previously negotiated JCT/NEC contract. Most worryingly of all, your building may not be as safe as it should be.

As manufacturers and installers, we are not here to devise a fire strategy, nor are we qualified to do so. As such, this article is orientated towards those who are involved in the contractor procurement process, and to those who have to interpret client design requirements and procure on their behalf. Our role is to thoroughly scrutinise any architectural specification, fire strategy, or building control requirements, references and inferences, then marry (if our product range allows, and it almost certainly will), THE CORRECT type of fire curtain, control systems and ancillary devices to your client strategy. To that end, it is imperative that we understand and cover off as a minimum your:

1) British and or European testing standards required i.e. BS 8524 or BS 1634

2) Required fire integrity to BS 1634-1

3) Radiation requirements in kw/m2 (for tenable conditions on the unexposed face of the curtain)

4) Whether smoke control to BS 1634-3 is required

5) Control functionality, i.e. one stage, two stage, time delay, etc.

6) Ancillary requirements, i.e. egress, and access switches, obstruction warnings and beacons

7) Fire curtain parameters and whether horizontal or vertical

8) Substrate we are fixing to

9) Any deflection stipulations

10) Required third-party accreditation hosted on Notified Body websites (so transparency and in the public domain) i.e. IFC certification for BS 8524 or Warrington Certifier for BS EN 1634-1

11) Installation, commissioning and servicing protocols to BS 8524-2 or BS 1634. Any required third party installer scheme.

If we were to get any part of this process wrong, no matter how seemingly minor, things can and unfortunately do, unravel very quickly. We also appreciate that our clients are probably contractually obliged to procure the correct system on behalf of their end client so unless we at the very least discuss all possible permutations with them, we are not doing our jobs properly. Sometimes disparities between the strategy and the specification may be legally the contractor’s responsibility to iron out. Similarly, if any fire curtain manufacturer does not discuss ALL of the above with you, in my personal opinion, they may well be introducing unnecessary commercial and life safety risk to your project.

For pricing and a discussion on your fire and smoke curtain projects email :

info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

A1S Group Secures CE Marked Fire Shutter Package for Cairo Opera House

A1S Group Secures CE Marked Fire Shutter Package for Cairo Opera House

The A1S Group has secured a specialist package to provide 7 “3 phase” JM range fire shutters with two to four-hour rating for Cairo’s opera house.

A1S Group Export Manager Mark Dougill was delighted to win A1’s fifth significant package in Egypt this year including the Egypt-Japan University of Alexandria, the Samsung Factory in Beni Suef as well as military bases which are subject to confidential non-disclosure agreements. Yet again the additional comfort of having a CE marked product, fully tested by Warrington Fire with the all-important Certificate of Constancy of Performance reassured the client that A1 had the leading products.

Get a quick quote today

A1S Group Wins Iconic Crescent Development Flameshield Fire Shutter package in Baku, Azerbaijan.

A1S Group Wins Iconic Crescent Development Flameshield Fire Shutter package in Baku, Azerbaijan.

There is always a commercial and pricing risk if a product exceeds the required specification on any given project. In this case the fact that our package included for CE marked fire shutters against the new harmonised European standard, EN BS 16034 turned out to be the salient winning factor and A1 are now in contract to manufacture 52 Flameshield FS 240 JM three phase fire shutters and 2 direct drive industrial doors for local installers Open Systems of Azerbaijan.

A1S Export manager, Mark Dougill correctly appraised that the end client, Gillan Holding LLC would want the comfort of CE Marking under the new stricter European testing regime, even though Azerbaijan are still in interim stages with mandatory CE marking.

The Crescent Development has its centrepiece as a crescent moon edifice with points on the surface of the Caspian Sea. Hosting a seven-star hotel and residential complex, this dazzling structure with its unique arcuate configuration mirroring the national flag of Azerbaijan is surely set to be Baku’s most iconic building and represents another global success for the A1S Group.

For any enquiries for fire rated shutters, fire curtains or industrial doors in Azerbaijan, please contact markdougill@a1shutters.co.uk

All Guns Aren’t Blazing as A1S Group Wins Fire Curtain Package for London’s Imperial War Museum.

All Guns Aren’t Blazing as A1S Group Wins Fire Curtain Package for London’s Imperial War Museum.

A combination of compliance and price has helped the A1S Group win the fire curtain package for the Imperial War Museum’s new creative hub annex. The main contractor Reds 10 selected A1S after a careful review of compliant submissions.

The requirement was for a fire curtain to BS 8524, specifically with third party accreditation by an external UKAS accreditation body (in this case IFC) and the Flameshield 8524 fire curtain was selected because of its ability to meet the required EW 60 classification of 120 minutes integrity performance and 85 minutes radiation at 15kw/m2. Careful analysis of the required BS 8524 annex testing, particularly C1 class Annex D durability testing, again satisfied the client that the A1s submission was the clear choice.

Winning this prestigious contract is another important contribution to the A1S group’s impressive portfolio of active fire barriers within museum and gallery building structures. Recent successes include, the National Archive, the British Postal Museum, the British Vehicle Museum and necessary replacement works for existing non-compliant fire curtains at Liverpool Museum.

Important comments for contractors involved in the procurement of Fire Shutters for steel, concrete and timber stud structures in the UK and Europe.

SYNOPSIS : Fire shutters cannot be CE marked without the relevant fire test documentation and CE marking is a legal requirement. All fire shutters must meet the new test regime. A fire shutter for timber stud MUST have a separate fire test to “flexible structure”. Assessments are no longer permissible. A1S has passed all required fire tests and can CE mark with end use either flexible or rigid. We have passed all required fire tests, have an Extended Application granting us the widest parameters and performance available in the UK and have completed mandatory factory audits. Finally, we hold the requisite Certificate of Constancy of Performance allowing us to CE Mark shutters as per our testing and within the guidelines of our Extended Application.

The harmonised European Standard EN 16034 was given the status of a national standard in April 2015 and conflicting national standards had to be withdrawn by October 2019. The period of coexistence allowing for non-CE marked fire shutters officially came to an end for the UK market on 1st November 2019.

There are now additional requirements for CE marking of powered fire shutters covered by EN 13241:2003+a2:2016. Compliance with the Construction Products Regulation (EU) 305/2011 (CPR) became mandatory. All new fire shutters must be fire tested and compliant to the latest harmonised standard and CE marked to both BS EN 16034:2014 AND BS EN 13241-1:2003. BS 1634-1 2014 is the relevant fire test.

As part of this process, if product fire testing to BS EN1634-1 2014 was to a rigid structure this then allows for installation into a rigid structure only i.e. steel and concrete. If a fire shutter is manufactured for “end use, a timber stud / drywall structure”, there must exist a separate fire test to such a “FLEXIBLE” structure. Section 13.5.1 of BS EN 1634-1 2014 indicates that test data from flexible structures are interchangeable with data from tests to rigid structures, but NOT the other way around which if you think about it is common sense. We have had this important detail confirmed in writing by Warrington Fire’s testing officer.

There is absolutely no wriggle room with this. If a fire shutter is to be used for a timber structure fire test evidence MUST be forthcoming. Furthermore, no separate test, no Extended Application Certificate Permission for timber stud. Desk top appraisals for alternative structures are no longer permissible. EXAP certification, is the document that allows increased dimensions from the parameters and tested structure of the fire shutter. It also allows a manufacturer to modify components to achieve greater dimensions and will cover permissible structures. Without this, you simply cannot put a shutter in to the market with dimensions greater than those tested on Warrington’s small testing rig. Page 35 of BS EN 15269-10 2011 which is the standard for extended application of test results for fire resistance for fire shutters says “RIGID TO STANDARD FLEXIBLE, NOT POSSIBLE WITHOUT SEPARATE TEST.” Before there can be any consideration for extended application the fire shutter must have been tested in accordance with EN 1634-1 to achieve a test result which could generate a classification in accordance with EN 13501-2 at least equal to the classification subsequently required from extended application considerations.

Conclusively, it is not acceptable that manufacturers introduce fire shutters into the marketplace knowing full well that the end application is fitted to timber stud on the basis of a rigid structure fire test only. Sub contractors cannot procure a fire shutter tested to masonry and then hope to fit it to timber. CE Marking new fire shutters is the law. Integral to legitimate CE marking is a manufacturer’s declaration of conformity. This declaration must cite compliance with and list the relevant standards. The standards dictate separate tests to 1) rigid- concrete, steel and 2) flexible – timber/stud.

Penalties for manufacturing and selling new fire shutters into the UK marketplace that are not CE marked, or not correctly CE marked include, enforcement notices, orders to remove a product from market, up to three months imprisonment and/or a fine of £5000 for company directors.

https://www.gov.uk/guidance/ce-marking#ce-marking-enforcement

So main contractors, shouldn’t in theory need to worry as logic dictates that no UK firm would flaunt the new legislation by supplying and installing a product without relevant testing, after all we are discussing life safety critical machinery. However, as a word of caution, a contractor would be in breach of any JCT/NEC contract by procuring incorrectly or non-CE marked fire shutters. Furthermore, installation of such fire shutters by an employer into a UK workplace is a breach of PUWER.

http://www.hse.gov.uk/work-equipment-machinery/puwer.htm

When providing new work equipment for use at work, you must ensure it conforms with the essential requirements of European Community law (for new machinery this means the Machinery Directive). You must check it:

· is CE marked

· comes with a Declaration of Conformity

· is provided with instructions in English

· is free from obvious defects – and that it remains so during its working life

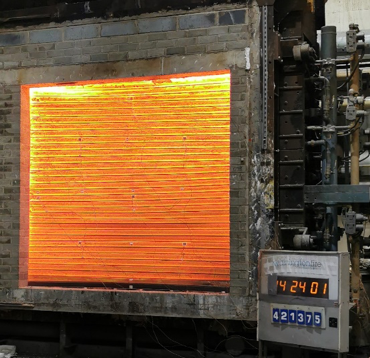

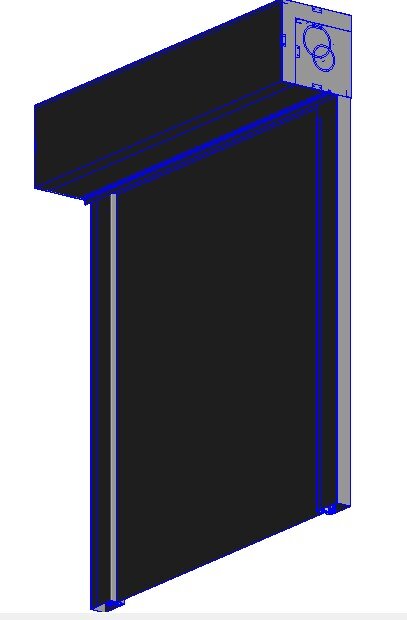

A1S Group 4-hour test to masonry (rigid)

A1S Group 1-hour fire test to timber (flexible)

UK Building Regulations, specifically Approved Document B make clear that fire and smoke resisting doors must comply with the relevant test standard(s). This is further reiterated by the Door and Hardware Federation Publication, “Changes to CE marking of Fire and Smoke Resisting Industrial Doors," and ADB in its Responsibility for Compliance Section states,

“People who are responsible for building work (e.g. agent, designer, builder or installer) must ensure that the work complies with all applicable requirements of the Building Regulations. The building owner may also be responsible for ensuring that work complies with the Building Regulations. If building work does not comply with the Building Regulations, the building owner may be served with an enforcement notice.”

The A1S Group has been manufacturing roller shutters, fire curtains and fire shutters since 1988. Having completed tens of 1000s of UK installations and as many “supply only” projects to our trade customers, experience tells us that the majority of “tube-motor” fire shutters are fitted into timber structures. Our assessment is that approximately 70% of what are commonly referred to as “tube” fire shutters are fitted to timber stud structures. A1S holds over 45 test certificates and accreditations including Warrington Certificate WF 421972 which successfully fire tested a tube motor fire shutter to timber or (flexible structure) for 1 hour and WF 421375 which successfully tested to masonry for 4 hours. rigid structure. We hold BS EN 15269-10 2011 Extended Application Certificate WF 422881 (Issue 1) for fire shutters to BOTH flexible and rigid structures. Within our EXAP we have the widest choice of parameters, and following the mandatory factory audits our fire shutters benefit from a mandatory Certificate of Constancy of Performance 1121-CPR-RA5009 to the harmonised standard of EN BS 16034-1 for E60, E120 and E240.

As of 03/12/2019 the A1S Group had passed ALL relevant fire testing in line with additional requirements for CE marking fire shutters. The A1S Group was the first UK company to pass the requisite fire tests to flexible (timber stud, steel stud or dry wall structures) AND rigid (masonry/steel) structures.

Contact:

info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

High End Student Accommodation Benefits From Flameshield Fire Curtains

High-End Student Accommodation Benefits From Flameshield Fire Curtains

A stone’s throw from the attractively named digital hub of “Silicon Roundabout” and next to London’s Old Street Tube Station sits IQ Shoreditch. Michael Brady Limited the main contractor on this high end £8.5 million student accommodation scheme for IQ chose the A1S Group to manufacture, install and commission six Flameshield fire curtains and smoke curtains to EN BS 1634-1 and EN BS 1634-3 in accordance with BS 8524-1.

A1S Group Flies High With Airbus Fire and Smoke Curtain Installation

The Welsh Government invested £20m to develop the first phase of its Advanced Manufacturing Research Facility in Broughton which will be operated by AMRC and used by Airbus for wing testing. Galliford Try were awarded the construction works as part of their ongoing North Wales Framework Agreement and after a smooth design process, chose the A1S Group for the supply and installation of 7 smoke control curtains to BS EN 12101 and 17 fire curtains tested in accordance with BS EN 1634-1 as required by BS 8524-1 2013 with 120 minutes integrity.

The photographs and video perfectly illustrate the physical differences between fire and smoke curtains and smoke curtains (only). The smoke only video displays curtains which do not descend within guides. Their purpose is primarily to channel smoke and as per their testing standard EN BS 12101-1, gaps are permissible and can be seen on the video. Permitted tolerances are as follows.

Up to 20mm when the curtain is less than 2 metres high

Up to 40mm when the curtain is between 2 and 6 metres high

Up to 60mm when the curtain is less than 6 metres high

The fire and smoke curtains on the two photos descend within guides and provide smoke leakage compliance to ENBS 1634-3 as well as their fire integrity to ENBS 1634-1 as required by BS 8524-1.

For any information about the A1S Group Flameshield fire and smoke curtain range, contact enquiries@a1shutters.co.uk for prompt customer and project support

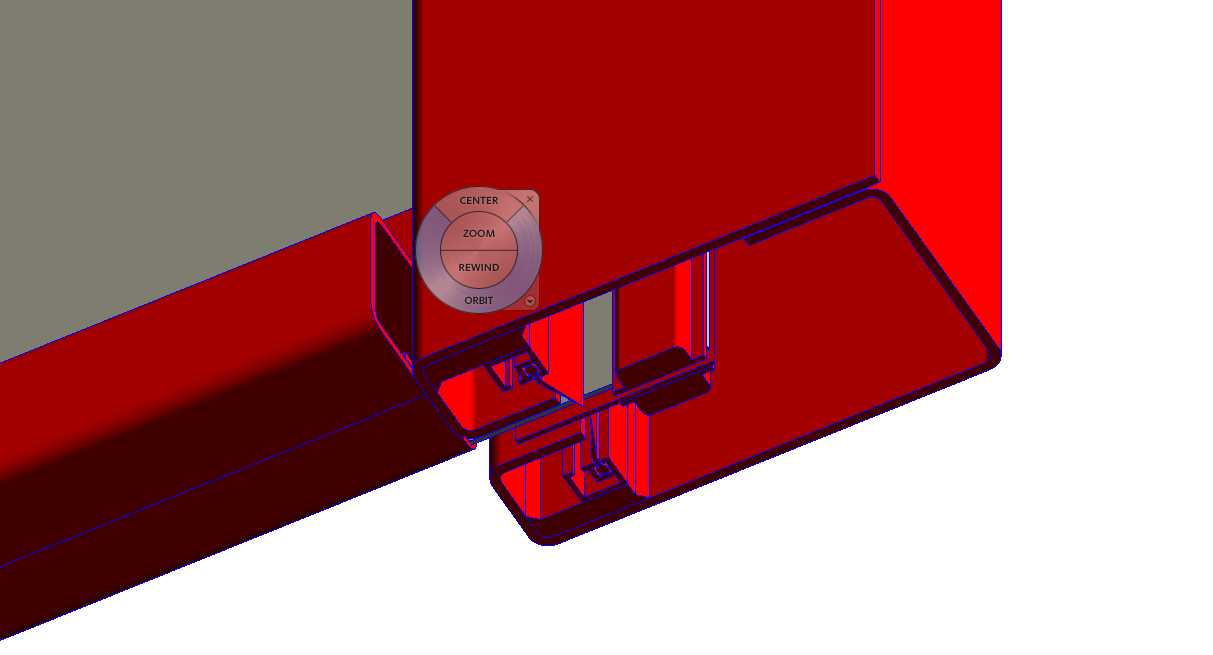

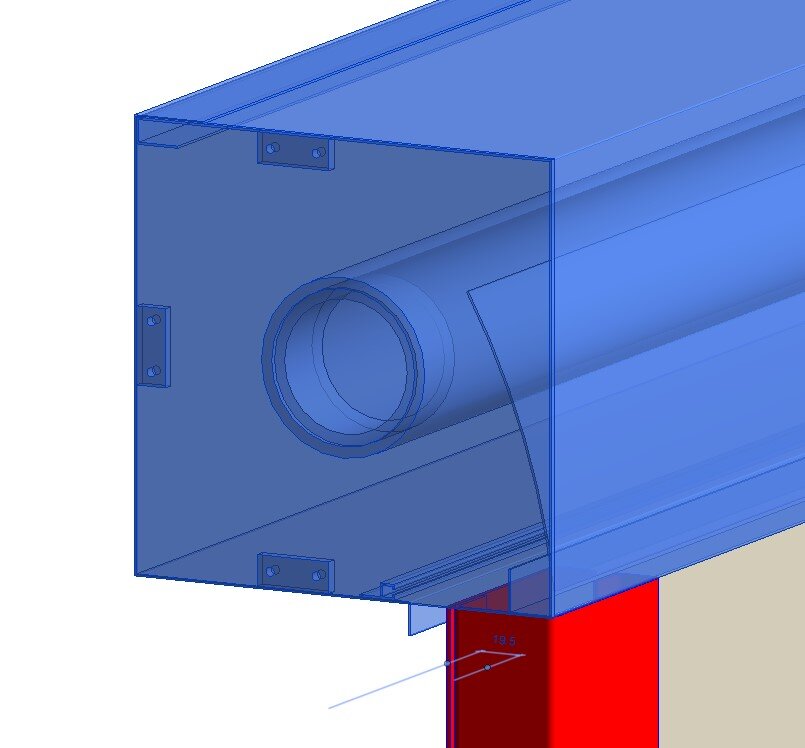

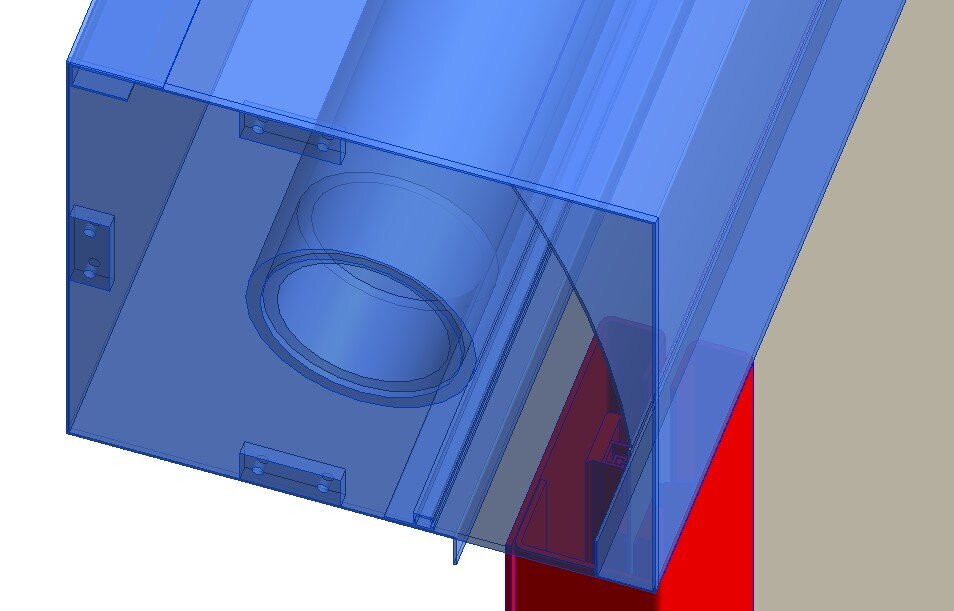

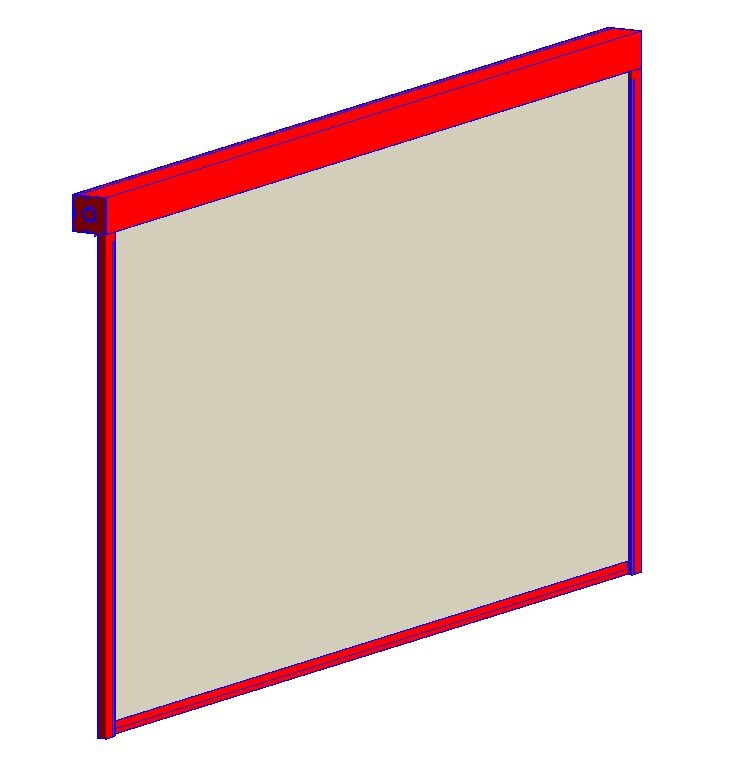

A1S Group Release Flameshield Fire Curtain BIM Models.

Revit files are NOW available including relevant COBie data for Flameshield 8524 fire curtain and Flameshield 8524S fire curtain with smoke seals.

A1S World Cup Stadium Shutters Package Ahead of Schedule

On time, and on budget is the report coming back from A1S Export manager Mark Dougill following his recent progress visit to Al Bayt stadium in Qatar.

This breath taking stadium design is based upon Bayt al Sha’ar tents, historically used by nomadic peoples in Qatar and the Gulf and is located 35km north of Doha in Al Khor City.

Working under the auspices of the Qatari Government’s Supreme Committee For Delivery and Legacy, A1S Group have manufactured 52 Flameshield Fire Shutters and 6 Industrial Shutters for this iconic World Cup 2022 stadium designed around sustainability.

On completion of the World Cup Finals, parts of the Al Bayt Stadium will be donated to a developing nation, as true to it’s nomadic heritage, the upper tier of the modular seating is removable.

A Huge Thank You To All Of Our Clients Who Visited Us At FIREX 2019

FIREX 2019 presented the A1S Group with an opportunity to meet UK and global clients, competitors, industry colleagues and exhibit their recently fire tested Flameshield EW120 fire curtain.

Chuck Lewis IFC Director and A1S Managing Director Carl Everest

A Huge Thank You to all of our Customers who Visited us at FIREX 2019.

FIREX 2019 presented the A1S Group with an opportunity to meet UK and global clients, competitors, industry colleagues and exhibit their recently fire tested Flameshield EW120 fire curtain. What a success it was! Whilst we had expected a degree of interest with our Flameshield EW 120, even an optimist would not have anticipated the industry reception. Interest particularly centred around low radiation ratings after fifteen minutes, thirty minutes and of course the achieved two-hour rating below 11kw/m2.

The advantages of exhibiting at FIREX over more general exhibitions became apparent with the multiple meetings with industry colleagues and we should express a particular thank you to Tony Corcoran from ASFP and Chuck Lewis, Director at IFC. We look forward to working with you both moving forward.

A1S Group to Exhibit at Firex International, London 18-20 June 2019

Come and see A1S at this the 2019 Firex International Exhibition. You can look forward to a warm welcome on stand FX 235.

Come and see A1S at this the 2019 Firex International Exhibition. You can look forward to a warm welcome on stand FX 235. A1S head of sales Paul Caldwell-Jones sees Europe’s only dedicated fire safety event as the perfect venue to showcase our market leading range of fire curtains and fire shutters to the industry.

“It has been a fantastic start to the year with UK Supply and Installation sales up 21% on 2018 and we see FIREX as a brilliant opportunity to meet both past, present and future clients. With the development of our new EW120 Flameshield fire curtain, we certainly have the wind in our sails and we can’t wait to discuss why our new fire curtain is generating such strong interest from the wider architectural and fire strategist community. “

Paul Caldwell-Jones - Head Of Sales

The A1S Group Cements A Global Reputation For Stadium Fire Curtains and Fire Shutters Winning Major Package For The Al Bayt 2022 Football World Cup Stadium In Qatar

The A1S Group Cements A Global Reputation For Stadium Fire Curtains and Fire Shutters Winning Major Package For The Al Bayt 2022 Football World Cup Stadium In Qatar

World Class

A1S Group Fire Shutters beat off strong global competition.

Building on A1S Group Flameshield Fire Curtains or Flameshield Fire Shutters being installed in the iconic Tottenham Hotspur Stadium (we were ahead of schedule), Wembley Stadium, Twickenham, Manchester’s Etihad, and the London Olympic Stadium, we have now secured the fire and industrial shutter package for the World Cup 2022 semi-final hosting Al Bayt Stadium.

Working alongside longstanding Middle Eastern partners Al Thuraya, A1S Group have secured the package for manufacture of 52 Flameshield Industrial Fire Shutters and 6 Industrial Roller Shutters. Mark Dougill export manager said, “It was our ability to manufacture fully compliant and accredited shutters up to 9.2 metres wide coupled with our project experience with Al Thuraya on the Doha Metro where we manufactured in excess of 100 insulated roller shutters that secured the package. Al Thuraya and the Qatari Aspire organisation were impressed with our heritage of manufacturing and installing in some of the world’s most iconic stadiums.”

Head of Sales and Marketing, Paul Caldwell-Jones said, “The Al Bayt Stadium contract represents another win for the A1S Group in 2019 on the back of contracts with Goldmann Sachs’s London Headquarters, the Royal College of Music and a raft of Manchester developments.”

And after the last semi final world cup disappointment, A1S Group are hoping to go one stage further than England did and get to the 2022 World Cup Final Lusail stadium in Doha with a brilliantly engineered fire shutter package. We’ll keep you posted.

The Fire Safety, Fire Curtain Revolution For UK Cinemas.

Did you realise that increasingly you are protected during a cinema visit by an A1S Group fire curtain? If you turn away from the screen, you will see the projector room, but there has been a sea change in many UK cinemas. What you won’t notice is a small bottom bar in the ceiling, above the glass, ready for a Flameshield fire curtain to descend on receipt of the fire alarm. The advent of IMAX and 3D Projection systems, whilst enhancing cinematic experience, led to a necessary revolution in projection room fire safety. Traditionally audiences have been protected with specialist fire rated glass between the projection room and the auditorium. Once IMAX and 3D projection systems were trialed, it became apparent that the properties of the fire rated glass distorted the picture quality. So what to do? Replace the fire rated glass with traditional float glass and compartmentalise the projection room with an A1S Group fire curtain with single stage descent. The perfect solution. To date, A1S has installed Flameshield EW 60 minute fire curtains in over 50 UK cinemas including Vue, Odeon, Everyman, Cineworld and Showcase. So if you ever watch Pulp Fiction in 3D (if only) you can rest assured, you are protected from fire in the projector room.

Rampant Confusion: Fire AND Smoke Curtains vs. Smoke Curtains. Which Standards Apply ?

Logic doesn’t always dictate, and top of the charts within our league for confused specifications is applying the wrong British Standard for fire and smoke curtains vs smoke “only” curtains.

The good news is that having successfully argued through the confusions with various building controls, fire strategists and quantity surveyors and with 100s of major UK projects under our belt, we feel we can clear this often made confusion up succinctly. BS 8524-2 also states,

“NOTE Smoke barriers, used solely for smoke control, are covered by BS EN 12101-1. Such smoke barriers are not considered to be active fire curtain barrier assemblies within the scope of BS 8524.”

1) Fire curtain only - BS 8524-1 or EN BS 1634-1

2) Fire and Smoke curtain (Floor to ceiling with guides) - BS 8524-1 or EN BS 1634-1 WITH EN BS 1634-3 which is the requisite air or smoke leakage test for a fire curtain. As a note, fire curtain specifiers should be aware that the rate of leakage through an active fire curtain must not exceed 3 m3/m/hr at a pressure of 25Pa when subject to a test utilising the principles of BS EN 1634-3:2004 along with the additional guidance for calculating the leakage rate provided with Annex F of BS 8524-1 2013.

The A1S Group significantly exceeded the requirements for this smoke leakage test. Because normal test specimens are fixed at a testing house (in our case Warrington Exova) with nominal structural opening sizes of 2000mm high by 2300mm wide, Annex F of BS 8524-1 provides additional guidance and assessments must be provided to specifiers to verify compliance when dimensions exceeding these sizes are required. The A1S Group holds Annex F BS 8524-1 certification to manufacture a fire curtain without smoke seals and certification and Warrington assessments to BS EN 1634-3 to 10000mm wide x 5630mm high with smoke seals whilst never exceeding the critical 3 m3/m/hr threshold.

3) Smoke Curtain (Only). The required standard is BS EN 12101-1. (As a guide, smoke curtains often will not require guides and will not descend completely to finished floor level. They are designed to channel smoke in conjunction with an HVAC system and do not provide fire integrity.

For further information on our range of Flameshield Fire Curtains, Fire and Smoke Curtains and Smoke Curtains only, please contact info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

The Difference Between Fire Curtains accredited to EN BS1634 and BS8524

Of course with the pricing differential between an EN BS 1634 curtain and a BS 8524 we are regularly asked what is the difference between the two relevant UK Fire Curtain standards in the UK. A recent client email via Arup pointed out the primary issue succinctly. “BS 8524 is the UK standard for an ACTIVE fire curtain.” And the active functionality and testing of a fire curtain is a good place to start if you wish to understand the differences between the two standards.

Previous to the publication of BS 8524, the only test requirements for Fire Curtains were their fire resistance and smoke control characteristics, i.e. integrity and radiation, Sa smoke classification and the now defunct insulation zone. As a company our fundamental argument was always that you can achieve the performance requirements as stipulated by Pas 121, BS 476 and EN BS 1634-1 with furnace testing, but that simply is not enough, because it is critically important to cyclic test fire curtains and smoke curtains to at least C1 Class i.e. a minimum of 500 cycles.

We are aware of test data from UK fire curtain manufacturers with non existent cyclic testing or where fabric fire curtains have been subjected to 25 manually operated and opening and closing cycles. A simple examination of the fabric, guides and poppers will often expose that the material within its build structure simply isn’t malleable enough to continually roll up and down. Yes it achieved a fire resistance rating during furnace testing, but how do you know you aren’t buying a cheap saucepan? Use it once and next time you burn your omelette. Our point is that if you have not replicated the life cycle of a fire curtain, how will you ever know that it will perform after commissioning, regular alarm inspections and mandatory servicing. You won’t. Which is why we are inundated with requests to replace non cyclic tested competitor curtains. The old adage, buy cheap buy twice comes to mind. But the proven robustness and long term performance of the product is not the only issue here. There is also an absolute requirement for this critical life safety equipment to properly function in an emergency. So difference one, a curtain to BS 8524 assures cyclic testing and thus reliability throughout the ten year plus life cycle of a fire curtain and life critical functionality in deployment situations.

Secondly BS 8524 fire curtains must pass an impact test to BS 5234-2, SD classification. BS 5234: Part 2 comprises a series of tests which examine a partition systems' suitability for a given partition duty. In the case of a fire curtain a fifty kilogram weight is swung into a central point of the curtain both before and after the cyclic test. The curtain must not leave its guides. This is purely to replicate the possibility of an individual falling or leaning into the curtain.

The third significant difference, and the part of BS 8524 that proved most difficult for manufacturers to achieve is the motor test (Annex G) to 400 degrees for thirty minutes. The issue for a fire curtain has always been once the fire breaks out, the immediate ceiling vicinity of the motor and head box will have the highest temperature. So why not replicate 400 degree conditions for 30 minutes? This is exactly what BS 8524 dictates. Only once the motor has been tested in a furnace to a minimum of 400 degrees for a minimum period of 30 minutes with a minimum of 12 cycles is it deemed to pass. And this is particularly critical for emergency services who will require the motor to still function once the access switch is activated or when the control panel is set for time delayed descent.

With the increasing use and requirement for ancillary equipment to give fire curtains additional functionality it makes sense to fully test each individual ancillary item in conjunction with the fire curtain and that is what Annex H now demands. Life safety fire curtains quite simply should not acquire additional functionality through untested bolt-ons. So whether it be egress or access switches, single or multi beam obstruction warnings, or smoke and heat detectors, a client can rest assured that the ancillary items have to be fully tested with a BS 8524 fire curtain.

Deployment speed must now test between (Vertical Curtain): ≥0.06 m/s at any height; ≤0.15 m/s below 2 m (Horizontal Curtain) : ≥0.06 m/s at any height; ≤0.3 m/s below 2 m. Too slow and the requisite integrity will not be achieved in a timely manner, too fast and the fire curtain is a danger to those under it.

The above changes and test requirements are given in the performance requirement table 5 of BS 8524-1. The table also includes further mandatory testing including reaction to fire. Fabric used in the construction of a barrier assembly shall be tested in accordance with BS 476-6 and BS 476-7 to achieve a Class 0 or Class 1 rating, or BS EN ISO 1716 or BS EN ISO 1182 and BS EN 13823 to achieve a minimum of B-s3,d2 (Class 0 equivalent) or a minimum of C-s3,d2 (Class 1 equivalent). Deflection data is also to be assessed.

All of the above testing is covered in one comprehensive UKAS accredited third party certification scheme from IFC to BS 8524-1. Our certificate number is IFCC 1542. This scheme assesses the entire testing regime and all relevant performance criteria. Increasingly UK building controls now publish documentation stipulating BS 8524 and third party accreditation from IFC as a requirement for fire curtains and we are aware of curtains being condemned as non-compliant without such documentation.

For further information on A1S Group range of BS 8524-1 Fire Curtains and BS 8524-2 Installation, please contact enquiries@a1shutters.co.uk or call 01204 383839

A1S Group is exhibiting Flameshield Fire Curtains at Big 5 in Dubai

A1S at Big 5

You can find Mark at Stand SS1 E143, Sheikh Saheed Hall no 1, next to International Fire Consultants.

A1S Group Fire Curtains in 2018 RIBA Stirling Prize Winning Bloomberg Building

A1S Group Fire Curtains discreet design lends to overall aesthetic of 2018 RIBA Stirling Prize Winning Bloomberg Building.

Now and again a project really stands out as something special, and from its inception, the Bloomberg European Headquarters proved to do just that. The A1S Group were contacted by the architectural team at Foster and Partners and main contractors Sir Robert McAlpine, to provide a discreet and compliant fire curtain solution for compartmentalisation and smoke control for ground floor core, ground floor lifts, upper tier atrium and the kitchen access lift.

We manufactured and installed Flameshield 120 minute integrity fire curtains with industry leading smoke control performance to BS 1634-3. The A1S Group project team worked carefully with client design teams to ensure that the fire curtains remained as inconspicuous as possible as per the detailed client brief. The installation was completed on budget and on time.

A lot has been made of Michael Bloomberg’s involvement in the project, and we can testify to his eye for detail and passion for every aspect of the project. He even sent a commemorative glass and handwritten letter thanking A1S Group for our endeavours. Group Managing Director Carl Everest said, “We are proud to have manufactured and installed life safety fire curtains for a once in a generation, monumental architectural achievement.”