The trouble with insulated fire curtains

It wouldn’t be an exaggeration to say that five times a week, a phone call or a fire strategy report and a fire curtain or fire curtains and smoke curtain specification lands on my desk with the requirement for insulated fire curtains or fire curtains tested with an insulation zone. From Building Control in Southampton, to an architectural practice in Singapore, the same question comes up time and time again.

“Do you manufacture fire curtains with 60 minutes, 90 minutes or 120 minutes integrity AND insulation? Or what are the EIs of your Flameshield fire curtain range?

Within overall fire resistance criteria, where E = Integrity and I = Insulation, the requirement is for EI 30, EI 60, EI 90 or EI 120. Now I know what is trying to be achieved - namely a fire curtain that will provide 30-120 minute integrity and protection from spread of flames and hot gases (E 120), coupled with defined measurements to prevent fire spread by spontaneous non-piloted combustion and radiation (total heat flux) and to protect people and property against exposure to high temperatures and associated risks.

The answer is that none of the leading Fire Curtain UK manufacturers produce an insulated fire curtain or a fire curtain with insulation properties to EI 30.60.90 and 120 minutes. They certainly should NOT be advertising such performance characteristics. Insulation properties (i.e. EI) are simply not available with fire curtains in the UK. If you think otherwise, please feel free to touch a millimetre thin fire curtain on it’s surface after 60 or 120 minutes. (And apologies to our European friends who still use this term although predominantly for insulating zone, or EI1 (tested at 25mm) and EI2 (tested at 100mm) this is a UK-centric article.) The only UK exception to this would be in conjunction with a sprinkler system but nobody is further than a desk top appraisal on this.

The misnomer associated with an insulated fire curtain was worsened with the misconceived introduction of an insulating zone for fire curtains in PAS 121 which mercifully was confined to the annals of fire curtain history and totally scrapped in July 2013 so the confusion is understandable. Updated and precise guidance is now available in BS 8524-2.

The reasons why are common sense, but do not worry about your project, there is good news and a documented alternative and clear guidance as to the use of radiation and radiation tenability data (instead of insulation) in the UK’s preeminent fire curtain standard BS 8524-2, Active fire curtain barrier assemblies – Part 2:Code of Practice for Application, Installation and Maintenance.

Page 13, 5.3.1 states that “Barrier assemblies replace static partitions and therefore have to descend within a clear space. Therefore the problems of surface temperatures DO NOT APPLY, but integrity, radiation and occupant tenability is still relevant.” A further note states that “Where it is impracticable to fix or hang thermocouples to the surface of the test specimen, as it would prevent the intumescent process working, the insulation performance of the specimen cannot be determined and the barrier assembly can only be tested for integrity and radiation.”

5.3.2.1 of BS 8524-2 continues, where radiated heat flux as opposed to insulation, is to be used to assess whether conditions are tenable, three distinct approaches should be used :

simplified approach for horizontal routes in dwellings (which can be explained based on the guidance in BS 8524)

fully fire engineered approach for horizontal escape routes (which I am not qualified to explain) but the guidance is on page 25 of BS 8524-2 with the important data and matrices on subsequent pages.

fully fire engineered approach for all other applications

I should definitely draw your attention to two pages of data B1 and B2 which provides permitted radiation performance, R maxA and accounts for minimum separation between escaping occupants and barrier assembly, d separation and speed of escaping occupants, v occupants. These indicate the performance criteria required from a fire curtain to achieve the requisite tenability. The definitive conclusion is that if your project requires active barrier fire curtains to form an exit route, they will definitively require testing to E for integrity and W for radiation so EW 30/60/90/120 not EI.

BS EN 13501-2 2016 also provisions for products to be classified as E or EW without insulation.

5.22.1 General states that, “Classification for integrity (E) shall be according to whether or not the element is also classified for insulation (I, I1 or I2). Where an element is classified both for integrity and insulation, the value of integrity is that determined by whichever of the three aspects fails first. Where an element is classified without an insulation classification (i.e. for the classifications E, EW, RE and REW), the value of integrity is that determined by the time to failure of only the cracks/openings or sustained flaming aspects, whichever fails first.

All A1S Group fire curtains are actually witness sampled, cyclic tested and furnace tested by Warrington Exova and within the test documentation is key radiation data, particularly kw/m2 at fifteen minutes and time elapsed before radiation reaches 15 kw/m2.

AS A NOTE THE A1S GROUP HAVE NOW SUCCESSFULLY TESTED THE UK’S FIRST EW120 CURTAIN, TO C1 CLASS WITH WARRINGTON FIRE WHICH ACHIEVED A UK INDUSTRY LOW 2.62 KW/M2 AT 15 MINUTES. 6.30 KW/M2 AT 1 HOUR AND 10.71 KW/M2 AT 120 MINUTES.

Hopefully, this article will complement the information you as a fire engineer or architectural specifier require for using the correct radiation data instead of the now defunct and highly confusing insulation data. Extended data sets including radiation minute readings between 0-120 are available on request to help establish which Flameshield fire curtain or indeed whether our product is even suitable for your application.

For details of A1S Group industry leading fire curtain radiation readings, must have test data and any general enquiries, please contact info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

The Difference Between A1S Group Fire and Smoke Curtains and Fire Shutters.

The Difference Between A1S Group Fire and Smoke Curtains and Fire Shutters.

For those not used to procuring these two distinct fire rated products, we thought it would be helpful to post a simple guide. Of course, procurement of fire curtains, fire and smoke curtains, smoke curtains and fire shutters can be a complex area. We advise that guidance is always taken from your Building Control, Design Team, and Fire Strategist – and of course with our significant project experience, we are always here to help.

1) Components

The first obvious difference between fabric fire curtains, fire and smoke curtains, smoke “only” curtains and fire shutters is the component build. Whilst both product ranges share commonalities, particularly as both are motorised and are generally activated by an alarm signal and generally descend within guide channels, a fire shutter is manufactured from, in our case 76mm curved solid galvanised steel lath. Curtains are manufactured from a range of tested fabrics, usually a heavyweight glass fabric which is reinforced with stainless steel wire, coated with a formulated fire-retardant aluminium pigmented polyurethane or intumescent fire-retardant silicon elastomer .

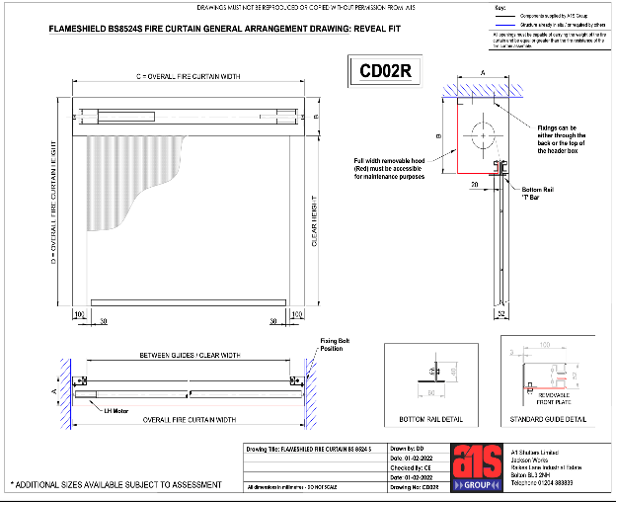

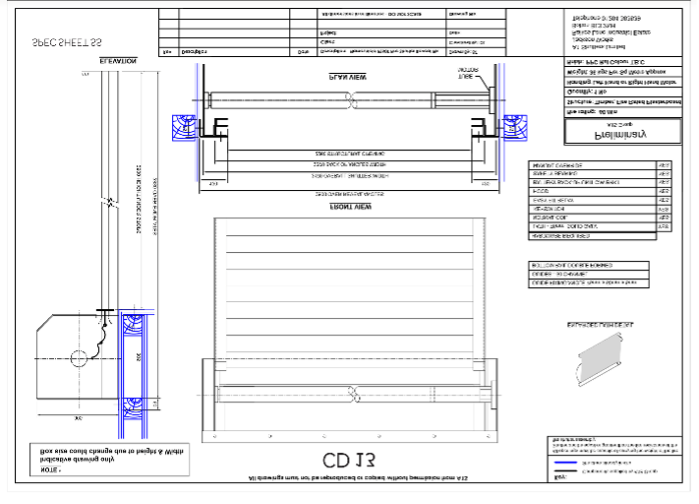

A1S Group fire curtain and fire shutter specifications and drawings are available at https://a1sgroup.com/specifications-and-drawings

2) Performance

Fire shutters are available with 1-, 2-, and 4-hour integrity and have been fire tested to BSEN 1634-1. Fire curtains are available with 1- and 2-hour integrity and additionally our Flameshield fire curtain range provides 85 minutes before breaching 15 kw/m2 radiation for the unexposed side of a curtain. Neither product is sold with insulating properties. Fire curtains provide smoke compliance to BS EN 1634-3 with the inclusion of specialist smoke seals and as such make the product suitable for protecting means of escape. Smoke seals are burnt as part of the fire testing to confirm integrity of the whole product. Smoke compliance is not available with a fire shutter range because of ingress between the curved lath section. A fire shutter can provide a degree of physical security when in the closed position. Fire and smoke curtains are designed to sit within their headbox and only become operable during fire conditions or on receipt of an alarm signal. For more detail, please see :

Link: https://firecurtain.co.uk/

Link: https://fireshutter.co.uk/

3) Standards

It is a legal requirement that fire shutters are manufactured under harmonised European standard BS EN 16034 and BS EN 13241. Our Flameshield range benefits from being the first tested to multiple substrates in the UK under this now required CE markable, and is approved for masonry, blockwork, structural steel and flexible stud systems.

Our Flameshield fire curtains are offered to BS 8524-1, BS EN 1634-1 as well as BS EN 1634-3 and we are finalising CE marking as despite preference for BS 8524 by many Building Controls in the UK the general direction of travel is for a CE marked fire curtain under BS EN 16034. Smoke “only” curtains are offered under the harmonised European Standard BS EN 12101. All of our fire testing is carried out by Warrington Fire, and we hold third party certification for both manufacture of fire curtains and installation of fire and smoke curtains under International Fire Consultants SDI 05 and SDP -11 02 Scheme.

4) Design

We host all indicative drawings across our product range at : https://a1sgroup.com/specifications-and-drawings

Both fire curtains and fire shutters benefit from internal tubular motors contained neatly within the head box. Fire shutters can also have external motors, generally where larger sizes are required. It is readily noticeable that fire shutters have larger head boxes which give fire curtains the edge when headroom is restricted. Permissible parameters for both ranges are available above. Likewise, both product ranges are available to be fitted to your structure either face fix or reveal fix. Indicative product weights are 22kg per linear metre for single vertical fire curtains, 36kg per linear metre for overlapping systems, and 35kg/m2 for fire shutters. Our testing documentation requires that all designed structures are load bearing to the above and have a fire performance equal to or greater than the performance required by our product. Fire curtains are also available as “horizontal” products to protect atria, light wells, escalators, and stairs from fire. Extended applications to BS 15269-10 and BS 15269-11 as well as product assessments from Warrington give further detail on structural requirements.

5) Applications

Fire and smoke curtains and fire shutters should be specified by trained and competent professionals. Broadly speaking fire shutters are used to provide integrity when there are openings in walls, for boundary protection and for compartmentation. Smoke only curtains are used to channel smoke, usually in conjunction with a ventilation system. Fire and smoke curtains can be used for, protected means of escape, egress and corridor separation, boundary protection, compartmentation, openings in walls and lift and lift lobbies.

For further information on our range of fire curtains, fire and smoke curtains and fire shutters, or any costing requirements, please contact :

info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

Still punching above our weight as A1S Invests In a C N C Punch System

Continuing our 2022 production investment, and targeted campaign to maintain the best fire and smoke curtain lead times in the UK.

A1S Invests In a C N C Punch System in Push to Maintain Sparkling Lead Times

Continuing our 2022 production investment, and targeted campaign to maintain the best fire curtain and smoke curtain lead times in the UK, the A1S Group has invested in an Amada Vipros 2510 King. Working in conjunction with Jetcam programming software we are now able to produce millimetre perfect head boxes, end guides, end plates, joining strips and a plethora of bracketry in an unlimited range of batch sizes, all with countersinking options. The state of the art punch system is to be utilised to manufacture metal works for third party certified Flameshield fire curtain and smoke curtains to BS 8524-1, Flameshield fire and smoke curtains to BSEN 1634-1, CE marked fire curtains to BS EN 16034 and our range of Smokeshield smoke curtains to BS EN 12101-1+A1:2005.

For information on our complete range of Flameshield fire curtains, fire and smoke curtains, and Smokeshield smoke curtains please email Paul Caldwell-Jones on paul@a1sgroup.com

Some Common Sense Guidance For Fire and Smoke Curtain Procurement

Better Safe than Sorry – some common-sense suggestions to cut through the smog of fire and smoke curtain procurement and guidance to avoid expensive and hazardous procurement pitfalls.

Better Safe than Sorry – some common-sense suggestions to cut through the smog of fire and smoke curtain procurement and guidance to avoid expensive and hazardous mistakes.

It’s always great to talk to clients, but in response to the same questions and scenarios coming up time and time again, it is worth hosting a few words on the dos and don’ts of fire curtain procurement, based on our experience as manufacturers and installers of fire and smoke curtains.

I am getting more and more feedback, especially on Design and Build contracts from Tier One Commercial Managers and Quantity Surveyors, that they haven’t budgeted enough, (despite our package being the most competitive) for the product and install package because their estimating team did not understand the permutations of products and British Standard options available and hadn’t understood the governing design of the fire strategy and curtain specification. Estimators are going to market and capturing costs that can sometimes increase dramatically because the products quoted are not in line with the building’s fire strategy. Absolutely no blame there. Fire and smoke curtains are notoriously difficult to get right. Often there are clues within a fire strategy, that unless you are used to them can trip you up. In our experience, a fire and smoke specification does not always align exactly with the fire strategy. There are often ambiguities and inconsistencies that require clarification and in every case before we price any project, we make sure that what is being quoted is going to be signed off by building control.

In recent months, the issue has become almost endemic and we are increasingly being asked to replace recently installed fire curtains from other manufacturers and installers as they did not meet ALL of the specification/British Standard testing requirements. For those who already know this then forgive the statement, but there are potentially hundreds of combinations of British Standard, functionality, integrity, radiation, ancillary, third party accreditation, parameters and related requirements that could be required for your project. Even worse than under-budgeting is if you get this wrong, you as a contractor could well be replacing your recently installed fire curtains, dismantling and rebuilding structures, delaying practical completion and warring with your end client on the legalities of catch all clauses such as “all current and relevant standards” in your previously negotiated JCT/NEC contract. Most worryingly of all, your building may not be as safe as it should be.

As manufacturers and installers, we are not here to devise a fire strategy, nor are we qualified to do so. As such, this article is orientated towards those who are involved in the contractor procurement process, and to those who have to interpret client design requirements and procure on their behalf. Our role is to thoroughly scrutinise any architectural specification, fire strategy, or building control requirements, references and inferences, then marry (if our product range allows, and it almost certainly will), THE CORRECT type of fire curtain, control systems and ancillary devices to your client strategy. To that end, it is imperative that we understand and cover off as a minimum your:

1) British and or European testing standards required i.e. BS 8524 or BS 1634

2) Required fire integrity to BS 1634-1

3) Radiation requirements in kw/m2 (for tenable conditions on the unexposed face of the curtain)

4) Whether smoke control to BS 1634-3 is required

5) Control functionality, i.e. one stage, two stage, time delay, etc.

6) Ancillary requirements, i.e. egress, and access switches, obstruction warnings and beacons

7) Fire curtain parameters and whether horizontal or vertical

8) Substrate we are fixing to

9) Any deflection stipulations

10) Required third-party accreditation hosted on Notified Body websites (so transparency and in the public domain) i.e. IFC certification for BS 8524 or Warrington Certifier for BS EN 1634-1

11) Installation, commissioning and servicing protocols to BS 8524-2 or BS 1634. Any required third party installer scheme.

If we were to get any part of this process wrong, no matter how seemingly minor, things can and unfortunately do, unravel very quickly. We also appreciate that our clients are probably contractually obliged to procure the correct system on behalf of their end client so unless we at the very least discuss all possible permutations with them, we are not doing our jobs properly. Sometimes disparities between the strategy and the specification may be legally the contractor’s responsibility to iron out. Similarly, if any fire curtain manufacturer does not discuss ALL of the above with you, in my personal opinion, they may well be introducing unnecessary commercial and life safety risk to your project.

For pricing and a discussion on your fire and smoke curtain projects email :

info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.