A1S Group Policy When Quoting UKCA* or CE Marked Fire Shutters For our UK and European Customers

The UK Government have extended the UKCA deadline until 2025.

CE (now UKCA for the UK or UKNI for Northern Ireland) marking of all powered doors under the machinery directive has been mandatory since 1995. This has not changed.

The following represents a simplified compliance guide to fire shutter certification following the mandatory changes and additional requirements due to the Construction Products Regulation (EU) 305/2011 which is NOW (as of 01/11/19) a legal requirement in Europe. UK Construction Products Regulations 2013 apply in the UK. A1 Shutters Limited’s certification is valid in both the UK and Europe and our UK notified body has established a subsidiary in the EU27 to facilitate this process.

1. As per our internal policy, we will always ask a customer if they are fully aware of the new legislation? If they say yes, we reconfirm that they know manufacturers must be able to provide installers with a certificate of constancy of performance. (see below) Without this the install is illegal as the product cannot be UKCA/CE marked. It is the installer’s responsibility to check this and there are serious legal consequences for the installer if the product is not UKCA/CE marked or perhaps more relevantly, correctly UKCA/CE marked. We will always check what structure, usage requirement, fire performance and dimensions the customer needs for the shutter before quoting.

2. If a customer is not familiar with the new harmonised legislation, we will ask what structure the shutter is to be fitted to, what fire performance is required, how many times a day the shutter will be used (to determine the appropriate motor) and what are the dimensions. We will then explain the following. Fire shutters must be UKCA/CE marked. It is illegal to manufacture a fire shutter without a UKCA/CE mark. It is illegal to install the shutter without a UKCA/CE mark. It is illegal for an employer or landlord to use a shutter that is not UKCA/CE marked. To be able to UKCA/CE mark, the manufacturer must go through the following process in its entirety.

3. Separate fire tests to flexible (timber stud) and rigid (steel/masonry) structures are now mandatory. If a manufacturer does not have any tests they cannot manufacture any fire shutter. If they have one test they can only manufacture a fire shutter for that end use, and the installer can only install to that one type of structure. The A1S Group has tested successfully to both flexible and rigid structures.

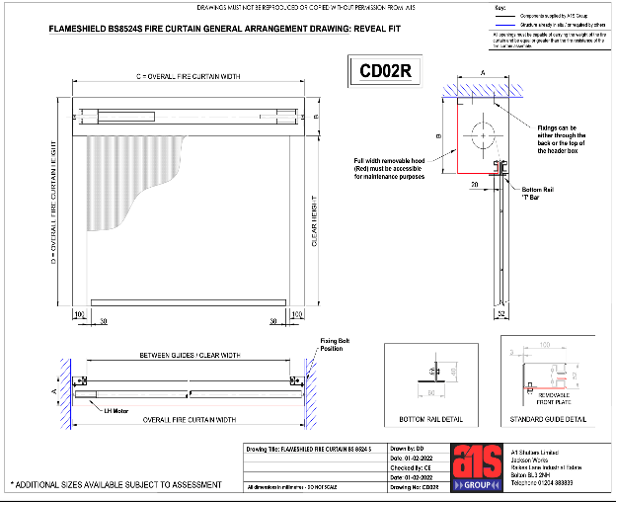

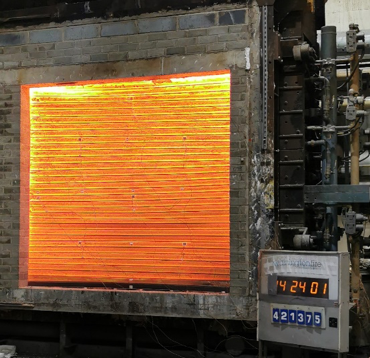

Flameshield fire shutters BS EN 1634-1 tested to 1 hour flexible structure and 4 hour rigid structures

4. Following the test an extended application MUST be provided by a notified body, i.e. Warrington. Certification must also be registered with an EU 27 notified body to be able to CE mark. Without an Extended Application, variant sizes on those tested CANNOT be manufactured. The document looks like this.

If a manufacturer cannot provide an EXAP, they cannot UKCA/CE mark so again the products are illegal and cannot be fitted or used. At the back of the EXAP are 12 pages of permissible sizes against structure and fire performance. Fire performance can be up to 240 minutes depending on the structure, and dimensions. If the required structure, size and performance is not on the EXAP, the product cannot be made. The matrices must be checked on every occasion. They look like this. If the matrices do not have a section for fitting to timber stud, the product CANNOT be used for such a structure and it is the responsibility of the installer and the end user to verify the manufacturer’s certification.

5. Factory audits are then required. No audits, no UKCA/CE mark.

6. Next, a Certificate of Constancy of Performance is granted to the manufacturer to verify fire resistance characteristics. It looks like this.

If a manufacturer cannot provide this document, the shutters are illegal as they cannot be UKCA/CE marked. There is absolutely no wriggle room and this document which can take many months to obtain following the test, audit and extended application process MUST be held at point of commissioning.

7. We must provide end users and installers with a Certificate of Conformity and a Declaration of Performance. Essential characteristics covered by EN BS 13241 and EN BS 16034 will always be cited on this document. This declaration can only be given by a company with the testing, extended application and certificate of constancy of performance in their name from a notified body, i.e. Warrington Fire. The certificates look like this. Variants now include UKCA and UKNI against the UK Construction Products Regulations 2013 as well as CE marking against Construction Products Regulation (EU) 305/2011.

8. All fire shutters must be UKCA/CE marked with a label against the relevant essential characteristics of both EN BS 13241 and EN BS 16034:2014 as well as the long-standing Machinery Directive. The UKCA/CE Marking label looks like this.

To conclude, as a company, we will always

1) Demonstrate proof of testing to both or the relevant flexible or rigid structure.

2) Reference our extended application matrices to confirm the shutter can be legally manufactured to the correct dimension, structure and fire performance.

3) Attach our certificate of constancy of performance to our quotation. This has been awarded because all other stages are completed along with requisite factory visits.

4) Provide our manufacturer’s declaration of performance and a certificate of conformity.

5) Finally, a correctly applied UKCA/CE label citing the machinery directive, BS EN 16034: 2014 and BS EN 13241 : 2003 + A 2 :2016 will be attached to every shutter. Audit is required from in our case Warrington Fire to confirm use of UKCA marking.

As of January 2021 CE, UKCA or UKNI labels should be used in the United Kingdom or Northern Ireland. If any part of this process is missed, a fire shutter is illegal to produce, install or use in the UK and Europe.

For a more detailed discussion or any general enquiries relating to UKCA/CE marking of fire shutters or the Construction Products Regulation (EU) 305/2011/UK Construction Products Regulations 2013, please contact info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

A National Regulator for Construction Products - There’s A New Sheriff in Town and he’s got a Retrospective Gun

Resulting from the horror of Grenfell and Dame Judith Hackitt’s subsequent review of building regulations, the UK Building Safety Bill 2022 has now received Royal Assent. (28th April 2022) The Building Safety Act 2022 will enshrine a Building Safety Regulator in law, who will provide oversight of the new system. They will have power of enforcement and sanction. The Building Safety Bill will create the authority to regulate construction products and create a statutory list of “safety critical” construction products where their failure would result in death or serious injury.

A separate regulator will also have powers to remove dangerous and non-certified products from the market. Last month the UK Government published a factsheet for this new National Regulator for Construction Products who will be established within the existing Office for Products and Safety Standards.

Not only will the new regulator maintain a national complaints hotline, they, will also lead and coordinate the enforcement of the strengthened construction products regulations, including removing products “that pose a safety risk from the market.” Powers will include entering, inspecting, and searching premises, requiring removal of products, and recovery of costs. Where a criminal offence has been committed under the new construction product regulations, “sanctions will include, fines, imprisonment or both.” Regulations will apply to any new product that a company wants to sell in the UK and to any existing products that a company continues to sell. Secondary legislation may take another 18 months, however the Government has also provisioned for retrospective action.

“Where a company previously sold a product that breached regulations, but no longer sells that product, the regulator may be able to act against the company for breaching the rules that were in place at the time of the offence”.

https://www.gov.uk/government/publications/building-safety-bill-factsheets/national-regulator-for-construction-products-factsheet

Obviously the new Regulator will sit across a broad range of life critical products. Our interest is fire rated barriers, and we suspect that given recent conversations we have had with contractors, fellow manufacturers, our internal marketing and industry sub contractors, there are potentially cases where fire shutters are still being installed into masonry, steel and timber stud structures without any legitimate CE marking paperwork, or incorrect paperwork. If you understand that 70 per cent of “tube motor” fire shutters in the UK are fitted into flexible stud structures, and you have a discussion with the very, few manufacturers who are compliant (and we think 2, maybe 3), the maths on unit manufacture nowhere near stack up. Unless we have our sums badly wrong, non-compliant products must be being installed. Likewise, masonry and steel fixing kits are potentially being used for timber stud structures - which if you have ever fire tested a shutter to BS EN 1634-1 is a catastrophic recipe for disaster. Manufacture and installation of fire shutters fall firmly within the remit of the new regulator as, they obviously fall under CPR 305/211 and are life safety products. The Door and Hardware Federation cite that “conforming to a hEN has legal consequences” and irrespective of BREXIT, hEN (Harmonised European Standards) apply. It follows that, fire shutter parameters must be set by an Extended Application (BS EN 15269-10) and no fire shutter can ever be installed into a flexible or timber stud structure if it does not have a separate fire test for such structures.

Compliant manufacturers will be able to demonstrate fire testing to multiple substrates within their Extended Applications.

Extract from A1S Group’s Extended Application to BSEN 15269-10 Evidencing Flexible AND Rigid Testing

The regulatory direction of travel for life critical products in the UK is clear, and the national complaints hotline will quickly and efficiently help expose breaches across the entire range of life safety construction products. Certainly, manufacturers and installers of life safety products will be under the microscope. Ignorance of CE marking and Construction Product Regulations will never be a defence, nor will obfuscation or confusion over any fixing structures and certification requirements under harmonised European Standards. Fines and retrospective costs could be crippling.

To reiterate, as a company, the A1S Group is accredited to manufacture fire shutters for BOTH flexible (timber stud) AND rigid (masonry and steel) structures. It is not our role to police manufacturer’s certification within our industry, but we are glad that there is a new sheriff in town.

For a simplified guide on the mandatory legislation and required certification from November 2019, please see: https://a1sgroup.com/blog/a1s-group-policy-when-quoting-ce-marked-fire-shutters

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

LET’S TURN “SILLY SEASON” INTO “SENSIBLE SEASON”.

If you have worked in UK construction for a few years, you are probably familiar with the phrase “silly season”.

What is “silly season?”

PRONOUNCED \ SIL-ee-SEE-zun\ noun

Silly Season is the time around late July/August when the newspapers are full of unimportant or silly news stories because there is not much political news to report.

[British English]

Well not at the A1S Group. “Silly season” for us, is when nearly every main UK contractor and most of our 250 trade partners are screaming for their fire curtains, smoke curtains, fire shutters and insulated shutters to come out of production from mid-July through to late August and even early September so that their school, college, and university projects can be completed during the summer holiday. The increased demand spike within the educational sector during such a small window effectively disrupts the entire construction industry, It is the time when our factory is absolutely flat out and when we have unprecedented demand for our installation teams. It is the time when clients are ringing and throwing accelerated payments around to try and obtain an impossible turnaround on packages because they are so up against practical completion.

And it never changes. Over the years we have tried limiting holidays (where possible), provisioned overtime, and put on additional shifts. And July to August is always hectic. Last year, we further invested in a CNC punch system to produce millimetre perfect head boxes, guides, end plates, joining strips and bracketry in a fraction of the usual time, and helped to keep fire and smoke curtain lead times around the three-to-four-week timeframe; but the truth is there are no guarantees. Lead times are always contingent on demand, but there are 2 things you can do which will definitely help us to maintain the best possible service for you and your project team.

1) Get your project on our radar as soon as possible, by emailing by return that our quote is of interest.

2) Let us know if you anticipate a production requirement of fire and smoke curtains, fire shutters and industrial shutters for July August or early September, thus allowing us to better plan.

Of course, we will always do our utmost to maintain what we think are the UK’s best lead times, and if you get truly stuck, we are here to be as accommodating as possible, but with your help and a little planning, we might well be able to look back in September 2023 and complement ourselves on how well “Sensible season” went.

To discuss forthcoming orders and installations for July/August/September 2023

FOR UK TRADE SALES CONTACT DAMIAN LAWSON

damianlawson@a1sgroup.com 01204 383839 ext 110

FOR UK SUPPLY AND INSTALLATION SALES CONTACT ANDY MARTIN

andy@a1sgroup.com 01204 383839 ext 104

The Difference Between A1S Group Fire and Smoke Curtains and Fire Shutters.

The Difference Between A1S Group Fire and Smoke Curtains and Fire Shutters.

For those not used to procuring these two distinct fire rated products, we thought it would be helpful to post a simple guide. Of course, procurement of fire curtains, fire and smoke curtains, smoke curtains and fire shutters can be a complex area. We advise that guidance is always taken from your Building Control, Design Team, and Fire Strategist – and of course with our significant project experience, we are always here to help.

1) Components

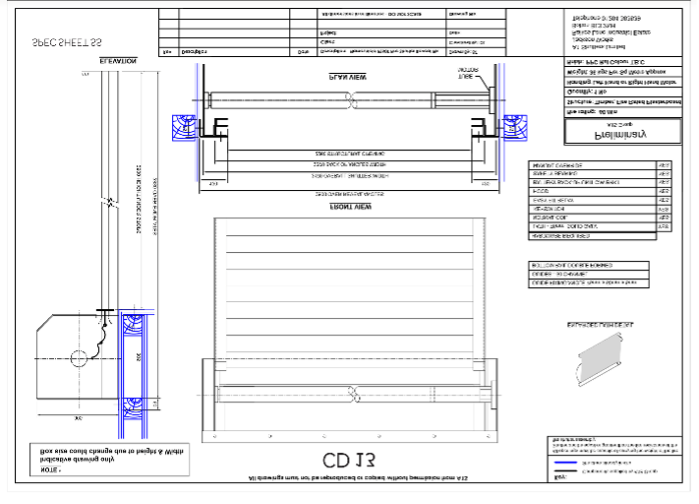

The first obvious difference between fabric fire curtains, fire and smoke curtains, smoke “only” curtains and fire shutters is the component build. Whilst both product ranges share commonalities, particularly as both are motorised and are generally activated by an alarm signal and generally descend within guide channels, a fire shutter is manufactured from, in our case 76mm curved solid galvanised steel lath. Curtains are manufactured from a range of tested fabrics, usually a heavyweight glass fabric which is reinforced with stainless steel wire, coated with a formulated fire-retardant aluminium pigmented polyurethane or intumescent fire-retardant silicon elastomer .

A1S Group fire curtain and fire shutter specifications and drawings are available at https://a1sgroup.com/specifications-and-drawings

2) Performance

Fire shutters are available with 1-, 2-, and 4-hour integrity and have been fire tested to BSEN 1634-1. Fire curtains are available with 1- and 2-hour integrity and additionally our Flameshield fire curtain range provides 85 minutes before breaching 15 kw/m2 radiation for the unexposed side of a curtain. Neither product is sold with insulating properties. Fire curtains provide smoke compliance to BS EN 1634-3 with the inclusion of specialist smoke seals and as such make the product suitable for protecting means of escape. Smoke seals are burnt as part of the fire testing to confirm integrity of the whole product. Smoke compliance is not available with a fire shutter range because of ingress between the curved lath section. A fire shutter can provide a degree of physical security when in the closed position. Fire and smoke curtains are designed to sit within their headbox and only become operable during fire conditions or on receipt of an alarm signal. For more detail, please see :

Link: https://firecurtain.co.uk/

Link: https://fireshutter.co.uk/

3) Standards

It is a legal requirement that fire shutters are manufactured under harmonised European standard BS EN 16034 and BS EN 13241. Our Flameshield range benefits from being the first tested to multiple substrates in the UK under this now required CE markable, and is approved for masonry, blockwork, structural steel and flexible stud systems.

Our Flameshield fire curtains are offered to BS 8524-1, BS EN 1634-1 as well as BS EN 1634-3 and we are finalising CE marking as despite preference for BS 8524 by many Building Controls in the UK the general direction of travel is for a CE marked fire curtain under BS EN 16034. Smoke “only” curtains are offered under the harmonised European Standard BS EN 12101. All of our fire testing is carried out by Warrington Fire, and we hold third party certification for both manufacture of fire curtains and installation of fire and smoke curtains under International Fire Consultants SDI 05 and SDP -11 02 Scheme.

4) Design

We host all indicative drawings across our product range at : https://a1sgroup.com/specifications-and-drawings

Both fire curtains and fire shutters benefit from internal tubular motors contained neatly within the head box. Fire shutters can also have external motors, generally where larger sizes are required. It is readily noticeable that fire shutters have larger head boxes which give fire curtains the edge when headroom is restricted. Permissible parameters for both ranges are available above. Likewise, both product ranges are available to be fitted to your structure either face fix or reveal fix. Indicative product weights are 22kg per linear metre for single vertical fire curtains, 36kg per linear metre for overlapping systems, and 35kg/m2 for fire shutters. Our testing documentation requires that all designed structures are load bearing to the above and have a fire performance equal to or greater than the performance required by our product. Fire curtains are also available as “horizontal” products to protect atria, light wells, escalators, and stairs from fire. Extended applications to BS 15269-10 and BS 15269-11 as well as product assessments from Warrington give further detail on structural requirements.

5) Applications

Fire and smoke curtains and fire shutters should be specified by trained and competent professionals. Broadly speaking fire shutters are used to provide integrity when there are openings in walls, for boundary protection and for compartmentation. Smoke only curtains are used to channel smoke, usually in conjunction with a ventilation system. Fire and smoke curtains can be used for, protected means of escape, egress and corridor separation, boundary protection, compartmentation, openings in walls and lift and lift lobbies.

For further information on our range of fire curtains, fire and smoke curtains and fire shutters, or any costing requirements, please contact :

info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

A1S Group in Irish Fire Shutter Supermarket Sweep.

It would seem that Ireland’s leading supermarket chains have developed a preference for A1S Group’s Flameshield Fire Shutter range.

A1S Group in Irish Fire Shutter Supermarket Sweep.

It would seem that Ireland’s leading supermarket chains have developed a preference for A1S Group’s Flameshield Fire Shutter range. With secure projects from Tesco, Aldi and Lidl in locations including the €5 million White Pines Store in Rathfarnham, County Dublin, a new store in Killarney and a store in Cahersiveen beginning Aldi’s 30 store roll out in Ireland as well as Lidl Ballymore. The export orders keep rolling in.

A1S Group’s Export manager Mark Dougill said, “I am delighted with securing so many supermarket projects in Ireland. End clients have identified the legal requirement in Ireland for CE marked fire shutters to BS EN 16034 that have been fire tested to multiple substrates, i.e., structural steel, masonry, and timber stud. I think our clients have switched on to the fact that our Flameshield fire shutter range covers the widest range of fire performance by structure and parameters and are ordering on the basis of our Extended Application which gives more design flexibility.”

The A1S Group offer Flameshield fire shutters with a maximum fire performance of four hours. At lower fire performance intervals we can manufacture up to 9000mm wide by 9000mm high. Our end clients always have the comfort that the entire range is CE marked to the harmonised European Standard of BS EN 16034. UKCA marking and UKNI marking is due to be introduced into Great Britain and Northern Ireland by January 2023. For a more in depth understanding of the testing process, required certification and regulatory background for CE marked fire shutters, please see,

https://a1sgroup.com/blog/a1s-group-policy-when-quoting-ce-marked-fire-shutters

For any specific export enquiries, please contact, markdougill@a1shutters.co.uk

For any sales or marketing enquiries, please contact, paul@a1sgroup.com

A1S Group Delighted to win Four Landmark Projects

In terms of iconic projects, we really are spoilt for choice this month with what is further recognition for our Flameshield fire shutter and fire curtain range.

In terms of iconic projects, we really are spoilt for choice this month with what is further recognition for our Flameshield fire shutter and fire curtain range. We had highlighted London Selfridges’ refurbishment, Edinburgh’s new John Lewis development, the stunning new (subject to NDA) Museum in Stratford and of course the majestic Katara Towers in Doha and hoped to win at least one of the projects.

Paul Caldwell-Jones, A1S Group Head of Sales and Marketing said, “To win all four projects is testament to A1’s growing reputation as a world leading fire shutter and fire curtain manufacturer and installer.“

A1S Group Export Manager Mark Dougill was particularly fulsome in his praise for Al Thuraya our Qatari partners who initially secured the Doha fire shutter package. “The Katara Towers will undoubtedly become one of the world’s most iconic structures,“ he said, “I am delighted to see our Flameshield shutters installed as a pivotal part of the fire strategy.” The imposing structure is an architectural translation of Qatar’s national seal representing traditional scimitar swords.

Flameshield fire shutters, in particular Flameshield FS240 JMs are to be manufactured and installed as part of the fire strategy for the John Lewis £20 million fit out in Edinburgh and Flameshield EW120 fire curtains are required for the (subject to NDA) Museum in London. This product retains the highest radiation performance for a UK fire curtain and is C1 class tested which is why it was selected by the design team at MCLH.

A1S Group Secures CE Marked Fire Shutter Package for Cairo Opera House

A1S Group Secures CE Marked Fire Shutter Package for Cairo Opera House

The A1S Group has secured a specialist package to provide 7 “3 phase” JM range fire shutters with two to four-hour rating for Cairo’s opera house.

A1S Group Export Manager Mark Dougill was delighted to win A1’s fifth significant package in Egypt this year including the Egypt-Japan University of Alexandria, the Samsung Factory in Beni Suef as well as military bases which are subject to confidential non-disclosure agreements. Yet again the additional comfort of having a CE marked product, fully tested by Warrington Fire with the all-important Certificate of Constancy of Performance reassured the client that A1 had the leading products.

Get a quick quote today

A1S Group Wins Iconic Crescent Development Flameshield Fire Shutter package in Baku, Azerbaijan.

A1S Group Wins Iconic Crescent Development Flameshield Fire Shutter package in Baku, Azerbaijan.

There is always a commercial and pricing risk if a product exceeds the required specification on any given project. In this case the fact that our package included for CE marked fire shutters against the new harmonised European standard, EN BS 16034 turned out to be the salient winning factor and A1 are now in contract to manufacture 52 Flameshield FS 240 JM three phase fire shutters and 2 direct drive industrial doors for local installers Open Systems of Azerbaijan.

A1S Export manager, Mark Dougill correctly appraised that the end client, Gillan Holding LLC would want the comfort of CE Marking under the new stricter European testing regime, even though Azerbaijan are still in interim stages with mandatory CE marking.

The Crescent Development has its centrepiece as a crescent moon edifice with points on the surface of the Caspian Sea. Hosting a seven-star hotel and residential complex, this dazzling structure with its unique arcuate configuration mirroring the national flag of Azerbaijan is surely set to be Baku’s most iconic building and represents another global success for the A1S Group.

For any enquiries for fire rated shutters, fire curtains or industrial doors in Azerbaijan, please contact markdougill@a1shutters.co.uk

Important comments for contractors involved in the procurement of Fire Shutters for steel, concrete and timber stud structures in the UK and Europe.

SYNOPSIS : Fire shutters cannot be CE marked without the relevant fire test documentation and CE marking is a legal requirement. All fire shutters must meet the new test regime. A fire shutter for timber stud MUST have a separate fire test to “flexible structure”. Assessments are no longer permissible. A1S has passed all required fire tests and can CE mark with end use either flexible or rigid. We have passed all required fire tests, have an Extended Application granting us the widest parameters and performance available in the UK and have completed mandatory factory audits. Finally, we hold the requisite Certificate of Constancy of Performance allowing us to CE Mark shutters as per our testing and within the guidelines of our Extended Application.

The harmonised European Standard EN 16034 was given the status of a national standard in April 2015 and conflicting national standards had to be withdrawn by October 2019. The period of coexistence allowing for non-CE marked fire shutters officially came to an end for the UK market on 1st November 2019.

There are now additional requirements for CE marking of powered fire shutters covered by EN 13241:2003+a2:2016. Compliance with the Construction Products Regulation (EU) 305/2011 (CPR) became mandatory. All new fire shutters must be fire tested and compliant to the latest harmonised standard and CE marked to both BS EN 16034:2014 AND BS EN 13241-1:2003. BS 1634-1 2014 is the relevant fire test.

As part of this process, if product fire testing to BS EN1634-1 2014 was to a rigid structure this then allows for installation into a rigid structure only i.e. steel and concrete. If a fire shutter is manufactured for “end use, a timber stud / drywall structure”, there must exist a separate fire test to such a “FLEXIBLE” structure. Section 13.5.1 of BS EN 1634-1 2014 indicates that test data from flexible structures are interchangeable with data from tests to rigid structures, but NOT the other way around which if you think about it is common sense. We have had this important detail confirmed in writing by Warrington Fire’s testing officer.

There is absolutely no wriggle room with this. If a fire shutter is to be used for a timber structure fire test evidence MUST be forthcoming. Furthermore, no separate test, no Extended Application Certificate Permission for timber stud. Desk top appraisals for alternative structures are no longer permissible. EXAP certification, is the document that allows increased dimensions from the parameters and tested structure of the fire shutter. It also allows a manufacturer to modify components to achieve greater dimensions and will cover permissible structures. Without this, you simply cannot put a shutter in to the market with dimensions greater than those tested on Warrington’s small testing rig. Page 35 of BS EN 15269-10 2011 which is the standard for extended application of test results for fire resistance for fire shutters says “RIGID TO STANDARD FLEXIBLE, NOT POSSIBLE WITHOUT SEPARATE TEST.” Before there can be any consideration for extended application the fire shutter must have been tested in accordance with EN 1634-1 to achieve a test result which could generate a classification in accordance with EN 13501-2 at least equal to the classification subsequently required from extended application considerations.

Conclusively, it is not acceptable that manufacturers introduce fire shutters into the marketplace knowing full well that the end application is fitted to timber stud on the basis of a rigid structure fire test only. Sub contractors cannot procure a fire shutter tested to masonry and then hope to fit it to timber. CE Marking new fire shutters is the law. Integral to legitimate CE marking is a manufacturer’s declaration of conformity. This declaration must cite compliance with and list the relevant standards. The standards dictate separate tests to 1) rigid- concrete, steel and 2) flexible – timber/stud.

Penalties for manufacturing and selling new fire shutters into the UK marketplace that are not CE marked, or not correctly CE marked include, enforcement notices, orders to remove a product from market, up to three months imprisonment and/or a fine of £5000 for company directors.

https://www.gov.uk/guidance/ce-marking#ce-marking-enforcement

So main contractors, shouldn’t in theory need to worry as logic dictates that no UK firm would flaunt the new legislation by supplying and installing a product without relevant testing, after all we are discussing life safety critical machinery. However, as a word of caution, a contractor would be in breach of any JCT/NEC contract by procuring incorrectly or non-CE marked fire shutters. Furthermore, installation of such fire shutters by an employer into a UK workplace is a breach of PUWER.

http://www.hse.gov.uk/work-equipment-machinery/puwer.htm

When providing new work equipment for use at work, you must ensure it conforms with the essential requirements of European Community law (for new machinery this means the Machinery Directive). You must check it:

· is CE marked

· comes with a Declaration of Conformity

· is provided with instructions in English

· is free from obvious defects – and that it remains so during its working life

A1S Group 4-hour test to masonry (rigid)

A1S Group 1-hour fire test to timber (flexible)

UK Building Regulations, specifically Approved Document B make clear that fire and smoke resisting doors must comply with the relevant test standard(s). This is further reiterated by the Door and Hardware Federation Publication, “Changes to CE marking of Fire and Smoke Resisting Industrial Doors," and ADB in its Responsibility for Compliance Section states,

“People who are responsible for building work (e.g. agent, designer, builder or installer) must ensure that the work complies with all applicable requirements of the Building Regulations. The building owner may also be responsible for ensuring that work complies with the Building Regulations. If building work does not comply with the Building Regulations, the building owner may be served with an enforcement notice.”

The A1S Group has been manufacturing roller shutters, fire curtains and fire shutters since 1988. Having completed tens of 1000s of UK installations and as many “supply only” projects to our trade customers, experience tells us that the majority of “tube-motor” fire shutters are fitted into timber structures. Our assessment is that approximately 70% of what are commonly referred to as “tube” fire shutters are fitted to timber stud structures. A1S holds over 45 test certificates and accreditations including Warrington Certificate WF 421972 which successfully fire tested a tube motor fire shutter to timber or (flexible structure) for 1 hour and WF 421375 which successfully tested to masonry for 4 hours. rigid structure. We hold BS EN 15269-10 2011 Extended Application Certificate WF 422881 (Issue 1) for fire shutters to BOTH flexible and rigid structures. Within our EXAP we have the widest choice of parameters, and following the mandatory factory audits our fire shutters benefit from a mandatory Certificate of Constancy of Performance 1121-CPR-RA5009 to the harmonised standard of EN BS 16034-1 for E60, E120 and E240.

As of 03/12/2019 the A1S Group had passed ALL relevant fire testing in line with additional requirements for CE marking fire shutters. The A1S Group was the first UK company to pass the requisite fire tests to flexible (timber stud, steel stud or dry wall structures) AND rigid (masonry/steel) structures.

Contact:

info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.