Important comments for contractors involved in the procurement of Fire Shutters for steel, concrete and timber stud structures in the UK and Europe.

SYNOPSIS : Fire shutters cannot be CE marked without the relevant fire test documentation and CE marking is a legal requirement. All fire shutters must meet the new test regime. A fire shutter for timber stud MUST have a separate fire test to “flexible structure”. Assessments are no longer permissible. A1S has passed all required fire tests and can CE mark with end use either flexible or rigid. We have passed all required fire tests, have an Extended Application granting us the widest parameters and performance available in the UK and have completed mandatory factory audits. Finally, we hold the requisite Certificate of Constancy of Performance allowing us to CE Mark shutters as per our testing and within the guidelines of our Extended Application.

The harmonised European Standard EN 16034 was given the status of a national standard in April 2015 and conflicting national standards had to be withdrawn by October 2019. The period of coexistence allowing for non-CE marked fire shutters officially came to an end for the UK market on 1st November 2019.

There are now additional requirements for CE marking of powered fire shutters covered by EN 13241:2003+a2:2016. Compliance with the Construction Products Regulation (EU) 305/2011 (CPR) became mandatory. All new fire shutters must be fire tested and compliant to the latest harmonised standard and CE marked to both BS EN 16034:2014 AND BS EN 13241-1:2003. BS 1634-1 2014 is the relevant fire test.

As part of this process, if product fire testing to BS EN1634-1 2014 was to a rigid structure this then allows for installation into a rigid structure only i.e. steel and concrete. If a fire shutter is manufactured for “end use, a timber stud / drywall structure”, there must exist a separate fire test to such a “FLEXIBLE” structure. Section 13.5.1 of BS EN 1634-1 2014 indicates that test data from flexible structures are interchangeable with data from tests to rigid structures, but NOT the other way around which if you think about it is common sense. We have had this important detail confirmed in writing by Warrington Fire’s testing officer.

There is absolutely no wriggle room with this. If a fire shutter is to be used for a timber structure fire test evidence MUST be forthcoming. Furthermore, no separate test, no Extended Application Certificate Permission for timber stud. Desk top appraisals for alternative structures are no longer permissible. EXAP certification, is the document that allows increased dimensions from the parameters and tested structure of the fire shutter. It also allows a manufacturer to modify components to achieve greater dimensions and will cover permissible structures. Without this, you simply cannot put a shutter in to the market with dimensions greater than those tested on Warrington’s small testing rig. Page 35 of BS EN 15269-10 2011 which is the standard for extended application of test results for fire resistance for fire shutters says “RIGID TO STANDARD FLEXIBLE, NOT POSSIBLE WITHOUT SEPARATE TEST.” Before there can be any consideration for extended application the fire shutter must have been tested in accordance with EN 1634-1 to achieve a test result which could generate a classification in accordance with EN 13501-2 at least equal to the classification subsequently required from extended application considerations.

Conclusively, it is not acceptable that manufacturers introduce fire shutters into the marketplace knowing full well that the end application is fitted to timber stud on the basis of a rigid structure fire test only. Sub contractors cannot procure a fire shutter tested to masonry and then hope to fit it to timber. CE Marking new fire shutters is the law. Integral to legitimate CE marking is a manufacturer’s declaration of conformity. This declaration must cite compliance with and list the relevant standards. The standards dictate separate tests to 1) rigid- concrete, steel and 2) flexible – timber/stud.

Penalties for manufacturing and selling new fire shutters into the UK marketplace that are not CE marked, or not correctly CE marked include, enforcement notices, orders to remove a product from market, up to three months imprisonment and/or a fine of £5000 for company directors.

https://www.gov.uk/guidance/ce-marking#ce-marking-enforcement

So main contractors, shouldn’t in theory need to worry as logic dictates that no UK firm would flaunt the new legislation by supplying and installing a product without relevant testing, after all we are discussing life safety critical machinery. However, as a word of caution, a contractor would be in breach of any JCT/NEC contract by procuring incorrectly or non-CE marked fire shutters. Furthermore, installation of such fire shutters by an employer into a UK workplace is a breach of PUWER.

http://www.hse.gov.uk/work-equipment-machinery/puwer.htm

When providing new work equipment for use at work, you must ensure it conforms with the essential requirements of European Community law (for new machinery this means the Machinery Directive). You must check it:

· is CE marked

· comes with a Declaration of Conformity

· is provided with instructions in English

· is free from obvious defects – and that it remains so during its working life

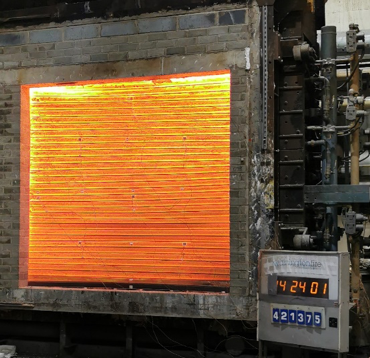

A1S Group 4-hour test to masonry (rigid)

A1S Group 1-hour fire test to timber (flexible)

UK Building Regulations, specifically Approved Document B make clear that fire and smoke resisting doors must comply with the relevant test standard(s). This is further reiterated by the Door and Hardware Federation Publication, “Changes to CE marking of Fire and Smoke Resisting Industrial Doors," and ADB in its Responsibility for Compliance Section states,

“People who are responsible for building work (e.g. agent, designer, builder or installer) must ensure that the work complies with all applicable requirements of the Building Regulations. The building owner may also be responsible for ensuring that work complies with the Building Regulations. If building work does not comply with the Building Regulations, the building owner may be served with an enforcement notice.”

The A1S Group has been manufacturing roller shutters, fire curtains and fire shutters since 1988. Having completed tens of 1000s of UK installations and as many “supply only” projects to our trade customers, experience tells us that the majority of “tube-motor” fire shutters are fitted into timber structures. Our assessment is that approximately 70% of what are commonly referred to as “tube” fire shutters are fitted to timber stud structures. A1S holds over 45 test certificates and accreditations including Warrington Certificate WF 421972 which successfully fire tested a tube motor fire shutter to timber or (flexible structure) for 1 hour and WF 421375 which successfully tested to masonry for 4 hours. rigid structure. We hold BS EN 15269-10 2011 Extended Application Certificate WF 422881 (Issue 1) for fire shutters to BOTH flexible and rigid structures. Within our EXAP we have the widest choice of parameters, and following the mandatory factory audits our fire shutters benefit from a mandatory Certificate of Constancy of Performance 1121-CPR-RA5009 to the harmonised standard of EN BS 16034-1 for E60, E120 and E240.

As of 03/12/2019 the A1S Group had passed ALL relevant fire testing in line with additional requirements for CE marking fire shutters. The A1S Group was the first UK company to pass the requisite fire tests to flexible (timber stud, steel stud or dry wall structures) AND rigid (masonry/steel) structures.

Contact:

info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.