Fire Protection in Buildings: Understanding Fire Classifications

Fire protection is a fundamental aspect of building safety and regulatory compliance. Fire classification systems have been developed for barrier products such as curtains, doors, and fire-resistant glazing to describe how effectively they limit the spread of fire. These classifications are standardised and product-agnostic, enabling designers and regulators to assess suitability with confidence.

By providing a consistent method of performance comparison, the system supports informed specification and compliance with fire strategies. When correctly applied, it plays a vital role in protecting life and property.

The three recognised fire classifications are E (integrity), EW (integrity and radiation), and EI (integrity and insulation). Each rating is expressed as a time in minutes and represents performance under controlled, standardised test conditions. The following sections explain how each classification is determined and how they should be interpreted in practice.

E (Integrity)

The E classification, also known as the integrity rating, is the most commonly specified fire performance level. It measures the ability of a separating element such as a fire curtain, door or shutter to withstand fire exposure on one side without allowing flames or hot gases to pass through to the unexposed side.

Testing is carried out using a furnace to raise the temperature on the fire-exposed side in excess of 1000°C, following a standard heating curve.

The test is terminated if there’s the formation of cracks or openings that exceed specified limits or sustained flaming on the unexposed side. Alternatively, the manufacturer may elect to stop the test once the required performance duration has been achieved.

It is important to note that an integrity test does not measure the transfer of heat through the product. This is addressed under the EW and EI classifications.

EW (Integrity and Radiation)

The EW classification builds upon the integrity test by also assessing the product’s ability to limit radiant heat transfer from the unexposed side. This is particularly important for maintaining tenable conditions in adjacent spaces and along escape routes.

During testing, two heat flux meters are positioned one metre from the unexposed face of the product. These instruments measure the thermal energy radiated across a defined area over time. One sensor is aligned with the centre of the specimen to determine an average heat flux, while the second is positioned to capture the maximum expected value.

The limits for radiation are exceeded once the radiometre exceeds 15kW/m2. The test is not concluded when the radiation exceeds 15kw/m2. The integrity test can continue providing no sustained flaming or gaps.

EI (Integrity and Insulation)

The EI classification is often required where fire separation must also limit heat transfer. In addition to maintaining integrity, the product must show no surface temperature increase on the unexposed side of the test specimen.

This characteristic is critical where occupants, escape routes, or combustible materials are located close to the barrier. By restricting temperature rise, the risk of secondary ignition and heat-related injury is significantly reduced.

Insulation performance is measured by monitoring the temperature on the unexposed surface. The test is terminated when this surface reaches a temperature of 140°C above the mean initial temperature recorded before the test, or when integrity failure occurs. Similarly to the EW classification, if the criteria for insulation is exceeded, the fire test can continue providing there is no sustained flaming or gaps.

Applying Classifications in the Correct Context

Fire classifications provide a common language for describing the performance of fire-resisting barriers and are essential to informed specification and regulatory approval. However, it is critical that these classifications are interpreted in the context of the product type and the applicable standards.

While the EI classification includes an insulation criterion, it is important to recognise that insulation performance is not a requirement for fire curtains under current UK guidance. BS 8524-1 and BS 8524-2 confirm that fire curtain barrier assemblies replace static partitions and therefore must descend within a clear space. Therefore, the problems of surface temperatures do not apply, but integrity, radiation, and occupant tenability are still relevant. BS 8524-2 further contains data within Tables B1 and B2 which indicates the performance criteria required from a fire curtain to achieve the requisite tenability.

For this reason, specifying an EI performance for a fire curtain is neither expected nor representative of how these systems are designed or tested in practice. Instead, fire curtains should be selected and assessed against the appropriate E or EW classifications, in line with the building fire strategy and the relevant standards.

Understanding the distinction between classification systems and product-specific performance requirements is essential for architects, fire engineers, and building control professionals. Correct interpretation ensures that fire curtains are specified for what they are designed to achieve, avoiding inappropriate expectations while maintaining robust life safety performance.

A1S Group Launches New Partner Programme to Empower Trade Partners

A1S Group is excited to announce the launch of our new Partner Programme, created to help trade partners grow their business and stand out in a competitive market.

Our partners will gain access to a wide range of benefits, including:

Industry-leading sales training to boost confidence and close more deals

Dedicated account support from our expert team

Professional marketing assets to strengthen brand presence

24-hour quote turnaround to keep projects moving fast

…and much more.

Mark Thornton, Head of Sales and Marketing at A1S Group, said:

“We’re committed to helping our trade partners thrive. The new Partner Programme gives them access to the training, support, and marketing tools they need to win more business and build stronger customer relationships.”

The A1S Partner Programme reflects our ongoing commitment to collaboration, growth, and shared success across the industry.

Learn more and apply for our Partner Programme: PARTNER PROGRAMME APPLICATION

Why a maintenance contract is critical: Are your fire curtains serviced and compliant?

When it comes to fire and smoke curtain systems, maintenance isn’t optional, it’s a legal and moral responsibility. These are not just pieces of equipment; they are life safety systems designed to protect people, buildings, and assets in the event of a fire.

Yet, far too often, systems go untested or neglected until it’s too late. That’s why A1S Group’s Maintenance Contracts are designed to remove uncertainty and ensure every system continues to perform exactly as designed; every time!

Guaranteed Piece of Mind

Under the UK’s Regulatory Reform (Fire Safety) Order 2005, the Responsible Person (whether a facilities manager, employer, or building owner) must ensure all fire safety systems are regularly inspected and maintained by competent professionals.

Fire and smoke curtains fall under this legislation and must be serviced at least every six months in accordance with BS 8524 and BS EN 12101. Failure to comply can lead to fines, prosecution, or, in the worst cases, catastrophic loss of life and invalidated insurance.

A maintenance contract with A1S Group provides complete peace of mind that these legal obligations are consistently met. Every visit includes certified testing, inspection, and full documentation, ensuring compliance is effortless and traceable.

The Hidden Cost of Neglect

A single unplanned failure can disrupt operations, delay projects, or compromise evacuation routes. Reactive repairs are not only more expensive but can also expose building owners to regulatory risk.

Through preventative maintenance, A1S identifies potential issues early, reducing the risk of costly downtime and keeping systems in optimal condition. This approach doesn’t just save money, it safeguards reputations and lives.

Why Choose A1S Group?

For over 37 years, A1S Group has been a trusted name in fire and smoke curtain manufacturing, installation, and servicing. Their service and maintenance clients benefit from:

Technical Expertise: The A1S service team includes engineers trained to handle complex and bespoke systems beyond the industry norm.

Nationwide Coverage: Operating across the UK, A1S offers responsive, professional support wherever it’s needed.

Experience in Live Environments: Skilled engineers perform maintenance safely and efficiently; even in occupied buildings, with minimal disruption.

Effortless Compliance

With a maintenance contract in place, you’re not just scheduling a service, you’re partnering with the original manufacturer. That means only A1S-certified engineers using genuine fire-rated components will handle your systems.

Every inspection includes detailed reporting, certification, and ongoing support to ensure your systems remain fully compliant and ready for any emergency.

Who Is Responsible for Maintenance?

Legally, the Responsible Person (typically the facilities manager, employer, or building owner) must ensure fire curtains are inspected and maintained. This responsibility cannot be delegated to chance.

An A1S maintenance contract helps Responsible Persons fulfil their duties confidently, knowing their systems meet every safety, insurance, and compliance requirement.

Book Your Service Today

Ensure your fire and smoke curtain systems are compliant, reliable, and ready to perform when it matters most.

To discuss a maintenance contract or book your inspection, contact A1S Group’s Service Team:

01204 383 839

service@a1sgroup.com

Book a Maintenance Contract

Why architects need to understand fire and smoke curtains

In modern architecture, where innovation meets regulation, architects are expected to deliver more than visually compelling spaces. They must ensure those spaces are safe, compliant, and built to last. Among the most critical, yet under-discussed elements in achieving this, are fire and smoke curtains. These life-saving systems play a central role in passive fire protection and can mean the difference between effective fire containment and catastrophic spread.

At A1S Group, we deliver Continuing Professional Development (CPD) sessions tailored specifically for architects. Our fire and smoke curtain CPD is designed to equip specifiers with the knowledge they need to make informed design decisions, reduce compliance risk, and ultimately protect lives.

Why Fire and Smoke Curtains Matter

Open-plan design, large atria, and complex multi-use buildings have become standard features of modern architecture. While these spaces enhance user experience and allow for creativity in design, they also present significant challenges in fire safety.

Fire and smoke curtains offer an elegant, high-performance solution. When deployed, they create temporary barriers that compartmentalise spaces, contain smoke and fire, and support safe evacuation routes. Crucially, they help buildings meet the demands of Approved Document B and BS 9999, as well as BS 8524 (for active fire curtain assemblies) and EN 12101-1 (for smoke control systems).

These systems are not just add-ons, they are essential for buildings that need to maintain open aesthetics without compromising fire protection. Yet, despite their importance, many architects are not fully aware of how these curtains work, where they are most effective, and how to specify them correctly.

The Risks of Getting it Wrong

Misunderstanding or overlooking fire and smoke curtains can lead to major design issues, costly changes late in a project, or non-compliance with building regulations. In some cases, poor specification can invalidate a building’s fire strategy altogether.

By sitting our CPD, architects can avoid these pitfalls with up-to-date technical knowledge and real-world application insights.

What You’ll Learn in the A1S Group CPD

Our CPD sessions are concise, informative, and grounded in practical application. Topics covered include:

● The role of fire and smoke curtains in modern building design.

● Overview of relevant legislation and standards.

● System types, deployment methods, and control options.

● Key factors in specification and integration into the design process.

● Case studies demonstrating correct use of curtain systems.

We also highlight product innovations and how these systems can be seamlessly incorporated into contemporary architecture without disrupting the visual or structural intent of a design.

Responsibly Enhancing Design Freedom

One of the major benefits architects discover through our CPD is how fire and smoke curtains can enable design freedom, rather than restrict it. For example, architects can create vast open lobbies, uninterrupted voids, or connected floor levels without breaching fire compartmentation rules; as long as appropriate curtains are specified and integrated correctly.

This flexibility makes curtains especially valuable in high-profile developments such as shopping centres, airports, hospitals, commercial offices, and mixed-use spaces where architectural ambition and public safety must go hand in hand.

For architects who want to stay at the forefront of compliant, future-ready design, this CPD delivers essential insight in under an hour.

Book Your CPD with A1S Group

To arrange an in-person or online CPD session for your practice or team, please contact us via cpd@a1sgroup.com or call us on 01204 383 839.

Which standard is truly designed to assess fire curtain performance, compliance, and safety?

Unfortunately, confusion still persists in the marketplace regarding the correct standard for active fire curtain barriers. To help clear this up, here’s the simplest way to explain the current situation.

Every application involving fire curtains should be assessed using BS 8524-1 & 2. In cases where a fire curtain is used as a replacement for a fire door, such as in a retail environment, BS EN 16034 may be referenced, but only when supported by additional testing to BS 8524-1. This is due to the significant testing shortfalls present in BS EN 16034 when applied to fire curtain systems.

To be absolutely clear:

Should BS EN 16034 ever be used as the sole standard for evaluating a fire curtain’s suitability for any application? No.

Does BS EN 16034 include any application, installation, or maintenance guidance relevant to fire curtains? No.

Does BS EN 16034 require or provide any form of installer certification? No.

BS EN 16034 was developed for pedestrian doorsets, industrial doors, commercial doors, garage doors, and openable windows; not fire curtain systems. In contrast, BS 8524 was specifically written for active fire curtain barrier assemblies.

Given this, the question becomes simple: which standard do you believe is truly designed to assess fire curtain performance, compliance, and safety?

The Importance of Radiation Performance in Fire and Smoke Curtains

When considering fire safety systems within buildings, fire and smoke curtains serve a critical function in limiting fire damage and safeguarding occupants. A key, yet sometimes overlooked, component of their effectiveness is radiation control. Radiation performance is vital in ensuring escape routes remain tenable and in reducing the risk of fire spread. Many products within the Flameshield range are approved by fire engineers and building control authorities specifically because of their exceptional radiation resistance.

Understanding Fire and Smoke Curtains

Fire and smoke curtains are deployable barriers designed to compartmentalise fires and contain the spread of smoke. They are automatically activated upon receiving an alarm signal, they descend to create protected escape paths and mitigate fire progression into adjoining areas. Additionally, they are frequently installed to protect boundaries near pedestrian areas or adjacent buildings. Their role is particularly significant in fire strategy planning, especially in modern structures where open layouts and complex evacuation routes are common.

What Is Thermal Radiation and Why Does It Matter?

In fire safety, radiation refers to the heat energy emitted by flames and heated surfaces, which can travel through space and ignite nearby combustible materials or cause injury to individuals. Effective control of this radiated heat is crucial for preventing secondary ignition and ensuring that escape routes and protected zones remain safe for evacuation.

The ability of a curtain to manage thermal radiation is determined by its heat resistance and its capacity to reduce heat transfer. High-performance curtains are engineered to withstand extreme temperatures while limiting the amount of radiated heat passing through. Fire curtains are typically tested to ensure radiation does not exceed 15 kW/m² at one metre.

BS 8524-1 & 2: What the Standard Says

The British Standard BS 8524-1 and BS 8524-2 govern the specification, application, installation, and maintenance of active fire curtain barrier assemblies. According to section 5.3.1 (page 13), "Barrier assemblies replace static partitions and therefore have

to descend within a clear space. Therefore the problems of surface temperatures DO NOT APPLY, but integrity, radiation and occupant tenability is still relevant."

It further notes that where thermocouple placement would impede the intumescent reaction of materials, insulation performance cannot be assessed, and thus the curtain must be evaluated solely for integrity and radiation performance.

Section 5.3.2.1 of BS 8524-2 outlines three approaches to assessing radiation in relation to tenability:

· A simplified approach for horizontal routes in residential dwellings.

· A fully fire-engineered approach for horizontal escape routes, with detailed guidance and data provided on page 25 and subsequent tables in BS 8524-2.

· A fully fire-engineered approach for all other applications.

Benefits of Radiation-Resistant Fire Curtains

1. Enhanced Occupant Safety Limiting thermal radiation ensures that escape routes remain usable and safe, supporting efficient evacuation during a fire.

2. Reduced Fire Spread By preventing nearby combustible materials from igniting due to radiant heat, these curtains help to contain the fire within a designated area.

3. Asset Protection Fire and smoke curtains safeguard critical infrastructure, sensitive equipment, and valuable assets from heat damage.

4. Regulatory Compliance Many building regulations require radiation control in fire barriers. Specifying radiation-rated curtains helps ensure compliance with relevant fire safety standards.

Technological Advances in Radiation Control

Modern fire and smoke curtains utilise advanced materials and engineering to improve radiation performance. Key innovations include:

· Intumescent Coatings These expand under heat, forming an insulating barrier that enhances thermal protection.

· Precision Engineering Ensures consistent, reliable deployment and optimal coverage, which is essential for maximum effectiveness during a fire.

Conclusion

Radiation performance is not merely a technical parameter; it is a critical life safety feature. As buildings become more complex, the demand for robust fire safety solutions intensifies. Specifying fire and smoke curtains with proven radiation control capabilities is essential for protecting lives, limiting property damage, and complying with modern safety standards.

A1S’s Flameshield EW120 S fire curtain offers industry-leading radiation protection and is fully compliant with BS 8524-1 and BS 8524-2. To learn more about our EW120 S Product visit: https://zma.to/har

A1S Fire & Smoke Curtains to Exhibit at The Fire Safety Event 2025

Birmingham, UK – 13th February 2025 – A1S Fire & Smoke Curtains, a leading manufacturer, installer, and global exporter of fire and smoke curtains, is thrilled to announce its participation in The Fire Safety Event 2025. The event is scheduled to take place from 8th to 10th April 2025, at the National Exhibition Centre (NEC) in Birmingham.

With over 30 years of experience, A1S Fire & Smoke Curtains has been at the forefront of delivering high-quality, British-made fire safety solutions. Their extensive product range includes vertical and horizontal fire curtains, smoke curtains, and fire and smoke curtains. The company has contributed to numerous landmark projects, such as Selfridges Oxford Street, Qatar 2022 World Cup Stadia, and the Bloomberg Building.

Carl Everest, Managing Director of A1S Fire & Smoke Curtains, expressed his enthusiasm about the upcoming event:

"We are excited to be attending The Fire Safety Event for the first time. This event will provide an excellent opportunity to showcase our innovative products and demonstrate our commitment to improving the fire safety industry."

Mick Speight, Operations Manager at A1S Fire & Smoke Curtains, also highlighted the significance of the exhibition:

"Participating in this event allows us to connect directly with industry professionals, discuss the technical aspects of our products, and explore collaborative opportunities to enhance fire safety across various sectors."

The Fire Safety Event is renowned for bringing together fire safety professionals, offering insights into the latest products and solutions in fire safety management. Attendees can look forward to CPD-accredited seminars, live demonstrations, and networking opportunities with experts and peers in the field.

A1S Fire & Smoke Curtains invites all attendees to visit their stand 4/M102 to learn more about their comprehensive range of fire safety solutions and discuss how they can assist in achieving the highest standards of fire protection.

Ensuring performance through regular maintenance

When it comes to fire safety, fire curtains are an essential component, providing both fire containment and smoke control. Below, we delve into what fire curtains are, their typical uses, and the importance of regular maintenance to ensure they remain compliant with current fire safety standards.

What Is a Fire Curtain?

Fire curtains are advanced fire safety systems designed to act as barriers during a fire. They are typically made from fire-resistant materials and deploy automatically when a fire is detected. Fire curtains are often integrated into a building's fire safety system, working alongside alarms and other fire safety products to slow the spread of fire and support safe evacuation routes. They are ideal for spaces where fixed barriers are not practical, offering customised solutions to fit various building designs and requirements.

Maintenance Requirements for Fire Curtains

To maintain the functionality and compliance of fire curtains with current safety regulations, regular and thorough servicing is crucial and lawful. Maintenance activities should encompass a detailed inspection of the deployment mechanism to ensure it operatescorrectly in an emergency, a close examination of the curtain fabric to detect any signs of wear or damage, and the replacement of any components.

Compliance with BS EN 16034 and, more critically, BS 8524 standards require not just routine checks but also strict adherence to servicing protocols. These standards are in place to guarantee the integrity, reliability, and safety of the fire curtain system.

For the product to remain compliant, servicing must be performed every six months exclusively by companies holding third-party accreditation to BS 8524 Part 2. This accreditation ensures that the service provider has demonstrated the expertise, processes, and quality controls necessary to meet stringent regulatory requirements. Furthermore, only the original manufacturer's replacement components must be used during maintenance. These will be the only components that are specifically designed and tested to work with the fire curtain system.

Under the Regulatory Reform (Fire Safety) Order 2005, it is the responsibility of the “Responsible Person” within a building to ensure that all fire safety products, including fire curtains, are properly maintained, tested and compliant. Failure to do so not only compromises safety but can result in legal consequences.

Why Choose A1S Group?

A1S Group is a leading UK manufacturer, installer, and exporter of fire curtains, offering high-quality, certified products tailored to diverse needs. Their systems follow stringent safety standards, including BS 8524 Part 1 and Part 2, and are backed by a 12-month guarantee. With extensive experience and a commitment to safety and compliance, A1S Group ensures that your fire curtains are always ready to perform when needed.

We are here to assist you to remain safe and compliant. For more information or to request a tailored quote, visit A1S Group's website.

The facts behind BS 8524 and BS EN 16034 in the UK fire curtain industry

In recent months, the UK fire curtain industry has been mired in confusion and opportunistic marketing tactics that misrepresent the facts. This situation arose following the International Fire Consultants (IFC) withdrawal from BS 8524-1 in June 2023. Unfortunately, some manufacturers and resellers in the UK have exploited this moment to propagate misleading claims designed to enhance their sales.

At A1S Fire & Smoke Curtains, we are committed to providing safe, compliant, and high-quality fire curtain solutions. We have collaborated with reputable experts to review industry standards and provide clear, accurate information.

The importance of BS 8524-1

BS 8524 remains the definitive standard for fire curtains in the UK, offering specific testing and operational criteria not covered by BS EN 16034. Sweco, an independent consultancy specialising in building standards, reviewed the issue and concluded:

“It is our opinion that fire curtain products with valid third-party certification to BS 8524-1 remain valid beyond the 9 June 2023 date of withdrawal, subject to:

No changes made to the design or manufacturing process since certification issue.

The manufacturer must continue to be ISO 9001 (or equivalent) accredited for fire and smoke curtain manufacture and evidence this.

Certification date current and set for a future expiration (many valid until 2025).”

Sweco further emphasised that BS 8524 is the only standard specifically designed for active fire curtains. In contrast, BS EN 16034 is broader in scope, encompassing doors, shutters, and other barriers, many of which are not suitable for fire curtain applications.

Please review their full report here: https://www.sweco.co.uk/services/building-standards/control/fire-curtains/

Clarifying the role of BS EN 16034

The Association of Specialist Fire Protection (ASFP), the UK’s leading authority on passive fire protection, has also weighed in. Their guidance states:

“The update of TD21 clarifies the foreword in BS EN 16034 states “Users’ attention is drawn to the fact that fabric curtains tested in this standard only apply to the fire door sets fire text. This standard does not cover their operation deployment speeds, initiation devices or warning devices, etc. and as such should comply with BS 8524-1 and BS 8524-2.”

Their full guidance can be found here: https://a1sgroup.com/blog/asfp-update-on-ukcace-marking-of-operable-fabric-curtains-fire-curtains

BS EN 16034 is more relevant to the European market, where its focus on industrial doors and shutters aligns with specific needs. However, in the UK, most fire curtain applications are better served by BS 8524. This standard incorporates rigorous requirements, including cycle tests (500 cycles prior to fire testing per Annex E) and reliability tests for motor operation and material durability.

Addressing misleading claims

Despite the clarity provided by industry experts, misinformation persists. Some companies claim that BS 8524 is “dangerous” and poses a “risk” without substantiating evidence. To protect prospect buyers, A1S advises:

· Always request to see certification documents

· Ensure the documentation originates from a reputable notified body

· Conduct due diligence when specifying fire curtains

Engagement with the OPSS

The Office for Product Safety and Standards (OPSS) is a government body whose primary purpose is to protect people and places from Product related harm, ensuring consumers and businesses can buy and sell products with confidence.

A1S has engaged in extensive discussions with the OPSS and conducted a comprehensive review of all pertinent information and standards applicable to the UK market. A1S’s findings reaffirm the critical role of BS 8524 in ensuring the safety and reliability of fire curtain products. BS EN 16034, while applicable under specific conditions, lacks key testing protocols such as cycle durability and elevated temperature motor reliability tests. This makes BS 8524 the superior choice for most UK applications, where rigorous performance criteria are essential to safeguarding people and property.

The OPSS has provided clear guidance, aligning with industry consensus from the ASFP, Sweco, and BSI, that fire curtain products with valid third-party BS 8524 certification remain compliant beyond the June 2023 withdrawal date, provided no design or manufacturing changes have occurred, ISO 9001 accreditation is maintained, and certifications are current. This clarity should guide all professionals involved in specifying, purchasing, or installing fire curtains in the UK.

The following points made by the OPSS were within the findings:

“There has been some uncertainty in the UK regarding the applicable operable fabric curtain standards in the UK. This was raised by [company name redacted] and we have carried out a review of the designated standards. Following a review of BS EN 16034 with regards to operable fabric curtain, this is currently our view of what is covered:

“The Scope of BS EN 16034:2014 is such that the standard applies (specific exclusions excepted) to a vertical fire curtain if it is a fire resisting and/or smoke control product intended to be used in fire and/or smoke compartmentation and/or escape routes and it is:

i) intended for installation in areas accessible to people and mainly intended for giving safe access for goods and vehicles (accompanied or driven by persons), and is any type of doorset (industrial, commercial or garage), rolling shutter or operable fabric curtain, or

ii) used in retail premises and mainly to provide access of persons rather than vehicles or goods, and is either a rolling shutter or operable fabric curtain, or

iii) intended to be installed in areas accessible to persons, and mainly for giving safe access for persons, and which is one of a hinged or sliding pedestrian doorset, openable window or inspection hatch.

These are the specific circumstances for the designated standards to apply and would agree with what ASFP and BSI have been saying.”

BS 8524 continues to cover 99% of applications within the UK and is expected to maintain this status. In contrast, BS EN 16034 is primarily designed for the European market, which explains the limited applications mentioned earlier. Fire curtains are rarely used for goods entrances, as fire shutters are typically preferred due to the specific environmental conditions. While fire curtains can be employed in retail settings, they are not suitable for doorways that experience constant use. This scenario would require the curtain to function like a standard door, being opened and closed hundreds of times daily. Since BS EN 16034 lacks a cycle test in its testing protocols, it poses a significant risk to use a curtain in such applications instead of a BS 8524 curtain, which has undergone a cycle test (500 cycles prior to fire testing as per Annex E).

16034 also does not have a testing method for

- Annex D (normative) Test method for barrier assembly reliability and response time and the durability of materials

- Annex G (normative) Test method for the reliability of motor operation at elevated temperatures

Addressing companies without Part 1 and Part 2

Since IFC made their withdrawal from BS 8524-1 in June 2023, companies in the industry have taken this as an opportunity to wrongly state that they have both BS 8524 Part 1 and BS 8524 Part 2.

The guidance given from industry professionals in the Industry OPSS, City of London Building Control, SWECO and ASFP with many others is that:

“fire curtain products with valid third-party certification to BS 8524-1 remain valid beyond the 9 June 2023 date of withdrawal, subject to:

No changes made to the design or manufacturing process since certification issue.

Manufacturer must continue to be ISO 9001 (or equivalent) accredited for fire and smoke curtain manufacture and evidence this.

Certification date current and set for a future expiration (many valid until 2025).

BS 8524 remains the only product specific test standard relevant to active fire curtains.

As such ASFP would point out that BS EN16034 and BS 8524 are not conflicting standards, but complimentary standards. It is recommended that where compliance with BS EN16034:2014 is mandated, this should still be augmented with certification to BS8524-1 and BS8524-2.

Designers and Specialists specifying fire curtains should carefully examine the documentation accompanying the products to ensure that it originates from a reputable Notified Body rather than the manufacturer. Therefore, we advise designers to conduct due diligence and scrutinise the documentation.”

When a company claims to be certified or tested to BS 8524, it's important to clarify this fact. The company should, and in most cases will, provide you with the appropriate certification. If they are unable to produce a reliable certificate, it may be due to them ‘self-certifying’ which is a misleading claim to being BS 8524 certified.

Setting the standard

At A1S Fire & Smoke Curtains, we take pride in manufacturing fire curtains that meet the highest standards. Unlike some competitors who import or resell uncertified products, our curtains undergo stringent quality checks in our UK factory. We welcome industry professionals to visit our UK manufacturing facilities and witness firsthand our manufacturing process.

The UK market relies on accurate and reliable information to ensure safety and compliance. The guidance from the OPSS, ASFP, and other authoritative bodies reaffirms the importance of BS 8524. Despite some companies anticipating validation of their claims, this has not materialised – a fact that is often disregarded. However, the market is beginning to reflect this shift towards transparency and accountability, with RIBA CPDs being withdrawn due to inaccuracies and fire engineers revisiting specifications that have been modified.

A1S GROUP JOINS NBS SOURCE TO EXPAND REACH WITH SPECIFIERS

A1S Group, a leading manufacturer, installer and global exporter of fire and smoke curtains to BS 8524, is proud to announce its inclusion on NBS Source, the trusted digital platform connecting manufacturers with specifiers in the construction industry.

With the growing demand for accessible digital information among specifiers, A1S Group has strategically chosen NBS Source to enhance its visibility and connect more effectively with this critical audience. The company will feature nine of its flagship products on the platform.

Boasting a reputation for first-class product excellence, A1S Group saw NBS Source as an ideal avenue to elevate its profile among built environment professionals. The platform allows specifiers to access detailed, accurate product and specification data, streamlining decision-making and ensuring they can find the right products for their construction projects.

In addition, NBS Source enables A1S Group to engage with specifiers throughout the entire construction lifecycle. This collaborative approach not only helps save time and resources for specifiers but also increases the likelihood of product selection by providing a seamless, efficient experience.

Enabling Smarter Specification

Carl Everest, Managing Director of A1S Group commented:

“At A1S Group, we prioritise understanding and addressing the needs of our customers. We recognised the challenges specifiers face in making well-informed decisions, and listing our products on NBS Source simplifies this process significantly. Specifiers can now quickly find, compare, and evaluate our products with ease.”

Lee Jones, Head of Manufacturer Solutions at NBS, added:

Specifiers want to make better and more informed decisions, and by having A1S Group listed on Source, this will make their lives easier. By giving specifiers access to the data they need, they can make accurate, direct comparisons, allowing them to be more decisive when choosing products and reducing the risk of mistakes.

He adds, “The full power of digital can only be unlocked through collaboration, and manufacturers such as A1S Group can now be involved. This is an important step in having a more structured approach to record-keeping and information management and promotes the ‘Golden Thread of Information’, which all manufacturers should be striving for.”

Adam Boulton, Head of Sales and Marketing commented:

“A1S Group recognises that the future of construction is digital, with specifiers increasingly relying on platforms like NBS Source. Being part of this ecosystem ensures our products are easily accessible during key stages of the construction journey, providing peace of mind that our solutions are always within reach.”

Explore A1S Group’s NBS Source listing: A1S Group

For more information, visit www.a1sgroup.com or contact 01204 383 839

Follow A1S Group on LinkedIn here: A1S Group LinkedIn

Getting The Right Support

Supporting Structure for Fire and Smoke Curtains

As manufacturers and installers of fire curtains and fire shutter we are often asked “What supporting structure is your Flameshield range of fire curtains tested/certified to?”

The reality is a fire test of a product is exactly that, it is a test of the product. It is not a test or certification of the substrate material itself.

So how do you confirm whether your structure is suitable for purpose? Hopefully the following information helps clarify.

The 2 main principles of forming an aperture designed to support a fire rated products are widely understood as follows:

Integrity - The supporting structure for a fire curtain must meet the required fire resistance period designed within a fire strategy or confirmed by a fire engineer. It would then be an architect’s job to specify a fire curtain which meets the performance required. A1S’s Fire curtains will likely outperform the structure as we test 120 minutes as a minimum. It’s important that the structure and a fire curtain works together to continue the fire line and provide the compartmentation required.

Weight - The weight of the curtain needs to be evaluated in designing the supporting structure. The fire rated structure must be capable of holding and maintaining the weight in a fire situation. A1S’s single vertical fire curtains weigh typically 22kgs per linear metre.

When installing fire and smoke curtains, it is important to understand that different fire tests are applicable for different structures. A fire test is required for rigid structures and a separate fire test would be required for fitting to flexible structures. Contained within any BS EN 1634-1 fire test document will be the following statement under the Supporting Construction Section. “The fire resistance of a door assembly tested in one form of standard supporting construction may or not apply when it is mounted in other types of construction. Generally, the rigid and flexible types are not interchangeable.” This is taken from BS EN 1634‑1:2014+A1:2018 13.5.1 General.

Apertures are split into two categories, either rigid or flexible.

A1S have tested and successfully passed our Flameshield range of fire curtains to blockwork and timber stud apertures designed to represent rigid and flexible support structure.

Rigid standard supporting constructions are further sub divided to high or low density as defined within EN 1363-1 Fire resistance tests –Part 1: General Requirements.

The responsibility of confirming whether your structure is within the “rigid” or “flexible” category would be your structural engineer/competent professional.

A1S Group awarded CE Marking

FLAMESHIELD BS EN 16034 FIRE CURTAINS

Flameshield 16034

Supporting the suite of products available to our export clients .

A1S Group are proud to announce CE Marking Accreditation for our Flameshield range of Fire Curtains is now available alongside our CE Marked Flameshield Fire Shutter range.

This accreditation represents another major milestone and underscores our compliance with Construction Products Regulations, ensuring the safety and reliability of our products. It not only fortifies our leading market position but also highlights our unwavering commitment to maintaining the highest industry standards.

Our portfolio of test certificates and certification to BS 8524 Part 1 and Part 2, further demonstrates our dedication to quality and regulatory compliance. This reflects our ongoing commitment to excellence and innovation in the fire safety industry.

The certification of our BS EN 16034 Flameshield Fire Curtains marks a significant step for future growth in Europe. Effective from 22 April 2024, it reflects our ongoing dedication to excellence and leadership in the fire safety industry. This achievement will undoubtedly bolster confidence among our customers and partners.

Our relentless pursuit of continuous development demonstrates our commitment to innovation and excellence. By staying at the forefront of fire safety standards, we ensure that our products meet the evolving needs of the industry and exceed customer expectations

ASFP Update On UKCA/CE Marking of Operable Fabric Curtains (Fire Curtains)

The Association of Specialist Fire Protection have released an update on Technical Document 21 relating to operable fabric curtains (fire curtains) and CE/UKCA marking. The update discusses the BS EN 16034 and BS 8524-1 standards and instances or which the scope of each standard is applicable

The Association of Specialist Fire Protection have released an update on Technical Document 21 relating to operable fabric curtains (fire curtains) and CE/UKCA marking. The update discusses the BS EN 16034 and BS 8524-1 standards and instances or which the scope of each standard is applicable

BS EN 16034

The update clearly identifies that the scope of BS EN 16034 only applies when a fire curtain is being used as a door to allow personal access / egress in retail premises and that the vast majority of fire curtains fall outside of this scope.

Unfortunately, due to misinformation provided by resellers of European manufactured fire curtains whose products are not sufficiently robust to meet the requirement of BS 8524, there has been confusion caused within the marketplace. Fire curtains are life critical safety product and the information being provided to aid procurement, if incorrect, can have a detrimental effect on a project’s cost and timeframes let alone the buildings occupants if it leads to procurement and installation of a non-compliant product.

The update of TD21 clarifies the foreword in BS EN 16034 states “Users’ attention is drawn to the fact that fabric curtains tested in this standard only apply to the fire door sets fire text. This standard does not cover their operation deployment speeds, initiation devices or warning devices, etc. and as such should comply with BS 8524-1 and BS 8524-2.”

In addition to the operations deployment speeds, initiation devices and warning devices mentioned above, BS EN 16034 also does not cover the hot motor test (operation after 30-minute, 400 degrees fire test) or cyclic testing to C1 Class (500 + cycles). in the opinion of A1S group the aforementioned tests are pivotal to a fire curtains life span and operational use in the event of a fire. The robustness of the standards and required testing is why, in our experience, Building Control, Architects and competent Fire Engineers demand fire curtains to BS 8524.

While BS EN 16034 is a valuable standard for evaluating the fire resistance of door and shutter assemblies, it should not be used as the sole basis for specifying fire curtains. The ASFP recommends that where the limited scope of BS EN 16034 applies, this should still be augmented with certification to BS 8524-1 and BS 8524-2.

BS 8524-1 specifically deals with the performance and testing of active fire curtain barrier assemblies, and it provides comprehensive guidelines and testing procedures for fire curtains, addressing their specific functionality and operation.

A1S Group wholeheartedly supporting the ASFP’s stance on BS 8524 1 and 2 as a national standard for fire curtains and the appropriate standard to use when specifying fire curtains to ensure they meet the necessary performance and fire safety requirements.

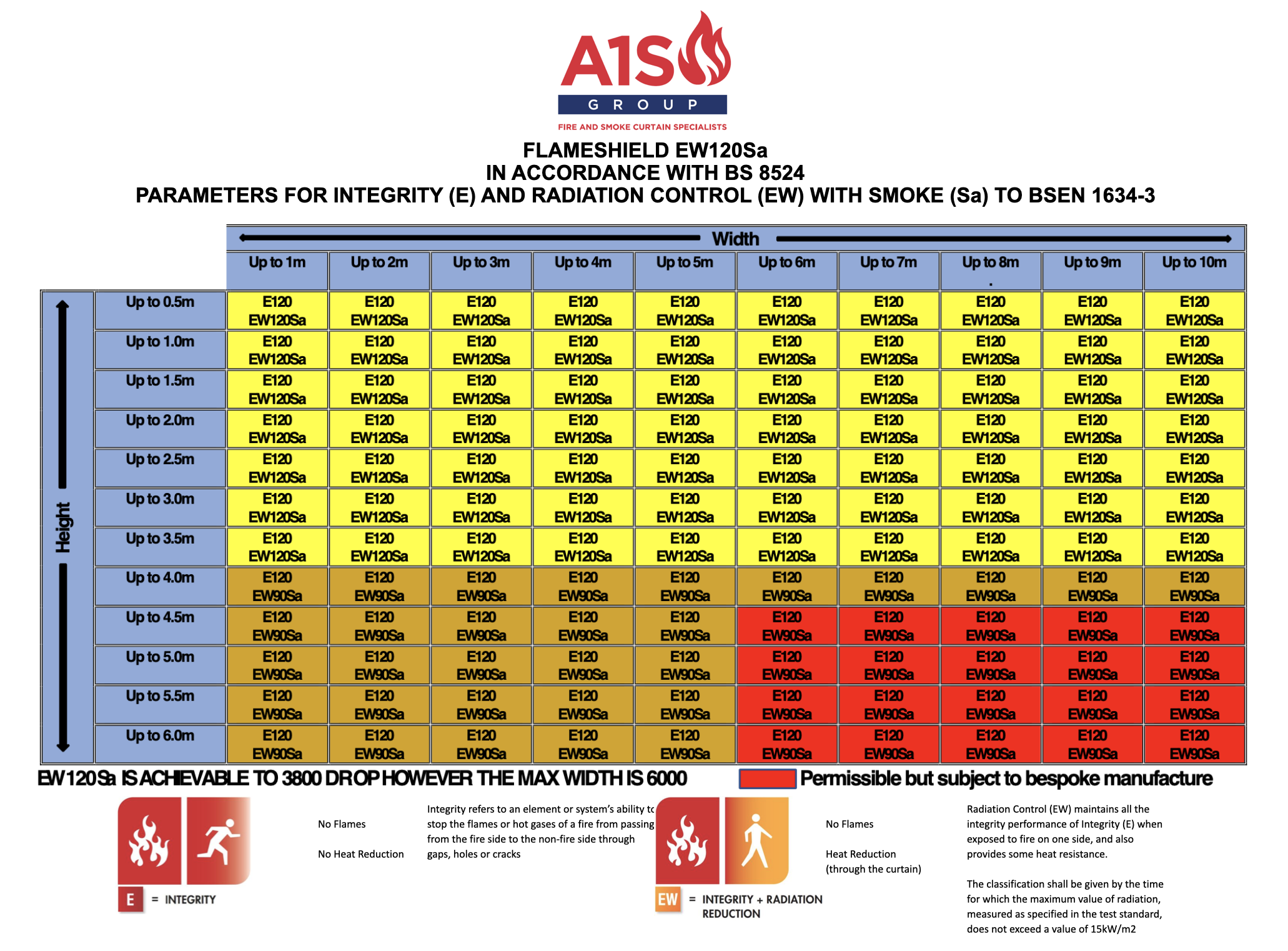

The Flameshield EW120 Sa to 10 metres wide

Unparalleled Radiation Performance across 10 metres

With Warrington Fire approving the Flameshield EW 120 with smoke seals to 10 metre widths, (WF Report no. 520547) based on Warrington Fire tests 405074/504026/504211 it is no surprise that orders and enquiries are coming in thick and fast for the UK’s highest radiation performance fire curtain. Designed to avoid any deflection of the bottom rail the video below shows the T- section rail sitting perfectly flush to the head box, giving a seamless finish.

The key performance benefit is the curtain’s ability to maintain BOTH 120 minute integrity and radiation levels below the required 15kw/m2 across the entire width of the 10000mm curtain to a drop height of 3600mm (see article) https://a1sgroup.com/blog/flameshield-ew120sa-fire-curtain The curtain is also approved to provide 120 minutes integrity and 90 minutes radiation below 15kw/m2 at a drop height of 6000mm.

As well as BS EN 1634-1 and BS EN 1634-3 testing, the curtain also benefits from BS 8524 testing including C1 class reliability and durability testing, elevated motor testing, response time and velocity testing.

Flameshield EW 120 Sa during inhouse development trials

This makes the curtain an ideal proposal for scenarios including protected means of escape, compartmentation, boundary protection and egress and corridor separation.

For further information, including enhanced data sets for calculations, please contact info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

Flameshield fire curtains now tested to 90 minutes for flexible (timber and stud) structures

Flameshield fire curtains now tested to 90 minutes for flexible (timber and stud) structures.

When installing fire and smoke curtains, it is important to understand that different fire tests are applicable for different structures. A fire test is required for rigid structures and a separate fire test would be required for fitting to flexible structures. Contained within any BS EN 1634-1 fire test document will be the following statement under the Supporting Construction Section. “The fire resistance of a door assembly tested in one form of standard supporting construction may or not apply when it is mounted in other types of construction. Generally, the rigid and flexible types are not interchangeable. “ This is taken from BS EN 1634‑1:2014+A1:2018 13.5.1 General.

Whether you are extending fire curtains as per BS EN 15269-11 Extended Applications for Fire Curtains or a UK assessment to general principles outlined in BS EN 15725, the guidance couldn’t be clearer. It is NOT POSSIBLE without an additional full scale fire test to fit a fire curtain to a flexible i.e. stud or timber structure. Fitting fire and smoke curtains to such flexible structures when the product has only been fire tested to rigid structures (i.e. brick) is potentially dangerous and irresponsible as well as contrary to the BS EN 1634-1 test standard enshrined within UK Building Regulations.

BS EN 15269-11 2018 (Part II Fire Resistance for operable fabric curtains) Page 32 (J1.2)

A1 had previously tested to a flexible stud system and achieved 60 minutes, but with increasing requests to achieve 90 minutes for a flexible structure we carried out a successful full scale fire test, Warrington reference 525487.

If you have any timber or stud system on your project, we would recommend that you ALWAYS ask to see the required fire test documentation showing testing to stud. Without this test evidence, you are running a genuine commercial risk that Building Control will not approve your installation; worse still you are risking that the fire curtain will not be fit for purpose. For further information on this test contact info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

The trouble with insulated fire curtains

It wouldn’t be an exaggeration to say that five times a week, a phone call or a fire strategy report and a fire curtain or fire curtains and smoke curtain specification lands on my desk with the requirement for insulated fire curtains or fire curtains tested with an insulation zone. From Building Control in Southampton, to an architectural practice in Singapore, the same question comes up time and time again.

“Do you manufacture fire curtains with 60 minutes, 90 minutes or 120 minutes integrity AND insulation? Or what are the EIs of your Flameshield fire curtain range?

Within overall fire resistance criteria, where E = Integrity and I = Insulation, the requirement is for EI 30, EI 60, EI 90 or EI 120. Now I know what is trying to be achieved - namely a fire curtain that will provide 30-120 minute integrity and protection from spread of flames and hot gases (E 120), coupled with defined measurements to prevent fire spread by spontaneous non-piloted combustion and radiation (total heat flux) and to protect people and property against exposure to high temperatures and associated risks.

The answer is that none of the leading Fire Curtain UK manufacturers produce an insulated fire curtain or a fire curtain with insulation properties to EI 30.60.90 and 120 minutes. They certainly should NOT be advertising such performance characteristics. Insulation properties (i.e. EI) are simply not available with fire curtains in the UK. If you think otherwise, please feel free to touch a millimetre thin fire curtain on it’s surface after 60 or 120 minutes. (And apologies to our European friends who still use this term although predominantly for insulating zone, or EI1 (tested at 25mm) and EI2 (tested at 100mm) this is a UK-centric article.) The only UK exception to this would be in conjunction with a sprinkler system but nobody is further than a desk top appraisal on this.

The misnomer associated with an insulated fire curtain was worsened with the misconceived introduction of an insulating zone for fire curtains in PAS 121 which mercifully was confined to the annals of fire curtain history and totally scrapped in July 2013 so the confusion is understandable. Updated and precise guidance is now available in BS 8524-2.

The reasons why are common sense, but do not worry about your project, there is good news and a documented alternative and clear guidance as to the use of radiation and radiation tenability data (instead of insulation) in the UK’s preeminent fire curtain standard BS 8524-2, Active fire curtain barrier assemblies – Part 2:Code of Practice for Application, Installation and Maintenance.

Page 13, 5.3.1 states that “Barrier assemblies replace static partitions and therefore have to descend within a clear space. Therefore the problems of surface temperatures DO NOT APPLY, but integrity, radiation and occupant tenability is still relevant.” A further note states that “Where it is impracticable to fix or hang thermocouples to the surface of the test specimen, as it would prevent the intumescent process working, the insulation performance of the specimen cannot be determined and the barrier assembly can only be tested for integrity and radiation.”

5.3.2.1 of BS 8524-2 continues, where radiated heat flux as opposed to insulation, is to be used to assess whether conditions are tenable, three distinct approaches should be used :

simplified approach for horizontal routes in dwellings (which can be explained based on the guidance in BS 8524)

fully fire engineered approach for horizontal escape routes (which I am not qualified to explain) but the guidance is on page 25 of BS 8524-2 with the important data and matrices on subsequent pages.

fully fire engineered approach for all other applications

I should definitely draw your attention to two pages of data B1 and B2 which provides permitted radiation performance, R maxA and accounts for minimum separation between escaping occupants and barrier assembly, d separation and speed of escaping occupants, v occupants. These indicate the performance criteria required from a fire curtain to achieve the requisite tenability. The definitive conclusion is that if your project requires active barrier fire curtains to form an exit route, they will definitively require testing to E for integrity and W for radiation so EW 30/60/90/120 not EI.

BS EN 13501-2 2016 also provisions for products to be classified as E or EW without insulation.

5.22.1 General states that, “Classification for integrity (E) shall be according to whether or not the element is also classified for insulation (I, I1 or I2). Where an element is classified both for integrity and insulation, the value of integrity is that determined by whichever of the three aspects fails first. Where an element is classified without an insulation classification (i.e. for the classifications E, EW, RE and REW), the value of integrity is that determined by the time to failure of only the cracks/openings or sustained flaming aspects, whichever fails first.

All A1S Group fire curtains are actually witness sampled, cyclic tested and furnace tested by Warrington Exova and within the test documentation is key radiation data, particularly kw/m2 at fifteen minutes and time elapsed before radiation reaches 15 kw/m2.

AS A NOTE THE A1S GROUP HAVE NOW SUCCESSFULLY TESTED THE UK’S FIRST EW120 CURTAIN, TO C1 CLASS WITH WARRINGTON FIRE WHICH ACHIEVED A UK INDUSTRY LOW 2.62 KW/M2 AT 15 MINUTES. 6.30 KW/M2 AT 1 HOUR AND 10.71 KW/M2 AT 120 MINUTES.

Hopefully, this article will complement the information you as a fire engineer or architectural specifier require for using the correct radiation data instead of the now defunct and highly confusing insulation data. Extended data sets including radiation minute readings between 0-120 are available on request to help establish which Flameshield fire curtain or indeed whether our product is even suitable for your application.

For details of A1S Group industry leading fire curtain radiation readings, must have test data and any general enquiries, please contact info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

The Flameshield EW120(Sa) Fire Curtain – Market Leading Fire Performance from the A1S Group

Is the Flameshield EW120 (Sa) from the A1S Group the UK’s leading performance fire curtain?

When you consider its permissible parameters, smoke testing, integrity and of course market leading radiation control, is the Flameshield EW120 (Sa) from the A1S Group the UK’s leading performance fire curtain? We think definitively yes. Certainly, with the life critical safety benefits of higher radiation control, we thought a thorough comparison between the UK’s leading products was more than merited. So we decided to take the Flameshield EW120 Sa for a “test drive” against other fire curtain manufacturer’s leading radiation performance single vertical curtains. The problem is only one other UK manufacturer appears to have completed the required test run AND responsibly published data and parameters in the public domain. Our view is that this transparency is fundamental in allowing fire professionals to make informed and sometimes life critical safety calculations.

Of course, both products have been fire tested by Warrington. They are tested in accordance with the “pass/fail annexes of BS 8524-1”, so as well as the fire test, response speed, impact testing, elevated motor testing, reliability and durability and testing of ancillaries are passed. Having completed the test run, the Flameshield EW120 is pending third party certification from an alternative scheme to IFC’s SDI 11-02 (8524-1 which is withdrawn) to comply with third party specification requirements when required.

It is the radiation performance from the actual fire testing where the Flameshield EW120 really starts to accelerate away. It is important to understand, whilst fire test documents must state radiation data, radiation performance diminishes as the curtain size increases beyond the original tested size so additional testing and assessment is required.

Beyond the Flameshield EW120 from the A1S Group, there appear to be no alternative published sizes for EW 120 – obviously because radiation levels breached 15kw/m2 well before 120 minutes. (Fact checked as of 08/09/2022) The only current and comparative data shows maximum published parameters for EW 90 at 2000mm x 7000mm or 3000mm x 3000mm, or 10000mm x 2000mm. So, the reality is no other company can legitimately manufacture a fire curtain to 3500 x 2200 for even EW90 let alone EW120.

Because the Flameshield EW120 only reached 10.7kw/m2 after 120 minutes – so nowhere near the limit of 15kw/m2, the sizes listed below are not just market leading, they create significantly improved tenability.

The importance is, this kind of radiation differential could potentially save occupant and building user lives, provide substantially more tenable environments for emergency services, and dramatically reduce thermal degradation of building fabrics.

There are many fire curtain applications where it is vital to assess the ability of “a separating element”, when exposed to fire on one side, to restrict the radiation on the “unexposed” side. The purpose of this blog is not to explain where and why there is a requirement for radiation control, that is the province of qualified fire strategists; rather it is designed to highlight the comparative data as published by the two leading radiation performance product manufacturers in the UK.

The above data is based on our EW120 fire test originally carried out on 01/01/2018. To reiterate, because tested sizes are approximately 2400mm wide by 2600mm high, (dictated by the size of Warrington’s test furnace) to compliantly manufacture and install larger products requires further test evidence. A small-scale test (Warrington reference 504026) was subsequently carried out as was a smoke leakage test Warrington reference WYC 504211), allowing Warrington to produce an Extended Size Assessment to include permissible substrates including steel and importantly permissible increased parameters for integrity, radiation, and smoke. Our Extended Size Assessment is Warrington reference 520457. The document cites the methodology under BS EN 15254-4:2018 and the calculations required to determine radiation intensity at larger sizes. We have published the results in matrix form below.

The above matrix describes radiation performance to higher levels and significantly larger parameters than anything else available (current as of 01/09/2022) in the UK; and because smoke seals were burnt during Flameshield fire testing our extended report cites, use of such seals at the published extended sizes to comply with the requirements of BS EN 1634-3. As a company we are getting significant and increasing interest from the wider fire community around the Flameshield EW120 (Sa). Specifications and drawings of this product are readily available for architects, fire strategists, design managers, quantity surveyors and Building Control at: https://firecurtain.co.uk/

For any other questions or comments on the Flameshield EW120(Sa) please contact

Our Sales Team on 01204 383839 or email sales@a1sgroup.com

Third Party Certification for Manufacture of Fire Curtains in Accordance with BS 8524-1

On the 23rd June 2022, International Fire Consultants (IFC) published a withdrawal notice on their website from “Product Certification Scheme for Active Fire Curtain Barrier Assemblies” (SDP11-02). With Warrington Fire also having withdrawn their EWCL5 scheme on the 16th December 2021, this effectively would leave the UK without a Third Party Certification scheme for BS 8524-1.

Discussions between alternative certifying bodies, the Association for Specialist Fire Protection (UK Trade Body) and leading manufacturers are already taking place.

In spite of IFC’s published notice, the A1S Group has received a letter (see below) from IFC offering a further year of Third-Party Certification under SDP11/02 to allow us to seek an alternative certifying body. As such, we will continue to manufacture fire curtains to BS 8524-1 under IFC’s Third Party scheme until 08th June 2023.

IFC’s Third Party scheme SDI 05 which covers the installation of fire curtains to BS 8524-2 is not currently affected.

A1S Group Policy When Quoting UKCA* or CE Marked Fire Shutters For our UK and European Customers

The UK Government have extended the UKCA deadline until 2025.

CE (now UKCA for the UK or UKNI for Northern Ireland) marking of all powered doors under the machinery directive has been mandatory since 1995. This has not changed.

The following represents a simplified compliance guide to fire shutter certification following the mandatory changes and additional requirements due to the Construction Products Regulation (EU) 305/2011 which is NOW (as of 01/11/19) a legal requirement in Europe. UK Construction Products Regulations 2013 apply in the UK. A1 Shutters Limited’s certification is valid in both the UK and Europe and our UK notified body has established a subsidiary in the EU27 to facilitate this process.

1. As per our internal policy, we will always ask a customer if they are fully aware of the new legislation? If they say yes, we reconfirm that they know manufacturers must be able to provide installers with a certificate of constancy of performance. (see below) Without this the install is illegal as the product cannot be UKCA/CE marked. It is the installer’s responsibility to check this and there are serious legal consequences for the installer if the product is not UKCA/CE marked or perhaps more relevantly, correctly UKCA/CE marked. We will always check what structure, usage requirement, fire performance and dimensions the customer needs for the shutter before quoting.

2. If a customer is not familiar with the new harmonised legislation, we will ask what structure the shutter is to be fitted to, what fire performance is required, how many times a day the shutter will be used (to determine the appropriate motor) and what are the dimensions. We will then explain the following. Fire shutters must be UKCA/CE marked. It is illegal to manufacture a fire shutter without a UKCA/CE mark. It is illegal to install the shutter without a UKCA/CE mark. It is illegal for an employer or landlord to use a shutter that is not UKCA/CE marked. To be able to UKCA/CE mark, the manufacturer must go through the following process in its entirety.

3. Separate fire tests to flexible (timber stud) and rigid (steel/masonry) structures are now mandatory. If a manufacturer does not have any tests they cannot manufacture any fire shutter. If they have one test they can only manufacture a fire shutter for that end use, and the installer can only install to that one type of structure. The A1S Group has tested successfully to both flexible and rigid structures.

Flameshield fire shutters BS EN 1634-1 tested to 1 hour flexible structure and 4 hour rigid structures

4. Following the test an extended application MUST be provided by a notified body, i.e. Warrington. Certification must also be registered with an EU 27 notified body to be able to CE mark. Without an Extended Application, variant sizes on those tested CANNOT be manufactured. The document looks like this.

If a manufacturer cannot provide an EXAP, they cannot UKCA/CE mark so again the products are illegal and cannot be fitted or used. At the back of the EXAP are 12 pages of permissible sizes against structure and fire performance. Fire performance can be up to 240 minutes depending on the structure, and dimensions. If the required structure, size and performance is not on the EXAP, the product cannot be made. The matrices must be checked on every occasion. They look like this. If the matrices do not have a section for fitting to timber stud, the product CANNOT be used for such a structure and it is the responsibility of the installer and the end user to verify the manufacturer’s certification.

5. Factory audits are then required. No audits, no UKCA/CE mark.

6. Next, a Certificate of Constancy of Performance is granted to the manufacturer to verify fire resistance characteristics. It looks like this.

If a manufacturer cannot provide this document, the shutters are illegal as they cannot be UKCA/CE marked. There is absolutely no wriggle room and this document which can take many months to obtain following the test, audit and extended application process MUST be held at point of commissioning.

7. We must provide end users and installers with a Certificate of Conformity and a Declaration of Performance. Essential characteristics covered by EN BS 13241 and EN BS 16034 will always be cited on this document. This declaration can only be given by a company with the testing, extended application and certificate of constancy of performance in their name from a notified body, i.e. Warrington Fire. The certificates look like this. Variants now include UKCA and UKNI against the UK Construction Products Regulations 2013 as well as CE marking against Construction Products Regulation (EU) 305/2011.

8. All fire shutters must be UKCA/CE marked with a label against the relevant essential characteristics of both EN BS 13241 and EN BS 16034:2014 as well as the long-standing Machinery Directive. The UKCA/CE Marking label looks like this.

To conclude, as a company, we will always

1) Demonstrate proof of testing to both or the relevant flexible or rigid structure.

2) Reference our extended application matrices to confirm the shutter can be legally manufactured to the correct dimension, structure and fire performance.

3) Attach our certificate of constancy of performance to our quotation. This has been awarded because all other stages are completed along with requisite factory visits.

4) Provide our manufacturer’s declaration of performance and a certificate of conformity.

5) Finally, a correctly applied UKCA/CE label citing the machinery directive, BS EN 16034: 2014 and BS EN 13241 : 2003 + A 2 :2016 will be attached to every shutter. Audit is required from in our case Warrington Fire to confirm use of UKCA marking.

As of January 2021 CE, UKCA or UKNI labels should be used in the United Kingdom or Northern Ireland. If any part of this process is missed, a fire shutter is illegal to produce, install or use in the UK and Europe.

For a more detailed discussion or any general enquiries relating to UKCA/CE marking of fire shutters or the Construction Products Regulation (EU) 305/2011/UK Construction Products Regulations 2013, please contact info@a1sgroup.com

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.

A National Regulator for Construction Products - There’s A New Sheriff in Town and he’s got a Retrospective Gun

Resulting from the horror of Grenfell and Dame Judith Hackitt’s subsequent review of building regulations, the UK Building Safety Bill 2022 has now received Royal Assent. (28th April 2022) The Building Safety Act 2022 will enshrine a Building Safety Regulator in law, who will provide oversight of the new system. They will have power of enforcement and sanction. The Building Safety Bill will create the authority to regulate construction products and create a statutory list of “safety critical” construction products where their failure would result in death or serious injury.

A separate regulator will also have powers to remove dangerous and non-certified products from the market. Last month the UK Government published a factsheet for this new National Regulator for Construction Products who will be established within the existing Office for Products and Safety Standards.

Not only will the new regulator maintain a national complaints hotline, they, will also lead and coordinate the enforcement of the strengthened construction products regulations, including removing products “that pose a safety risk from the market.” Powers will include entering, inspecting, and searching premises, requiring removal of products, and recovery of costs. Where a criminal offence has been committed under the new construction product regulations, “sanctions will include, fines, imprisonment or both.” Regulations will apply to any new product that a company wants to sell in the UK and to any existing products that a company continues to sell. Secondary legislation may take another 18 months, however the Government has also provisioned for retrospective action.

“Where a company previously sold a product that breached regulations, but no longer sells that product, the regulator may be able to act against the company for breaching the rules that were in place at the time of the offence”.

https://www.gov.uk/government/publications/building-safety-bill-factsheets/national-regulator-for-construction-products-factsheet

Obviously the new Regulator will sit across a broad range of life critical products. Our interest is fire rated barriers, and we suspect that given recent conversations we have had with contractors, fellow manufacturers, our internal marketing and industry sub contractors, there are potentially cases where fire shutters are still being installed into masonry, steel and timber stud structures without any legitimate CE marking paperwork, or incorrect paperwork. If you understand that 70 per cent of “tube motor” fire shutters in the UK are fitted into flexible stud structures, and you have a discussion with the very, few manufacturers who are compliant (and we think 2, maybe 3), the maths on unit manufacture nowhere near stack up. Unless we have our sums badly wrong, non-compliant products must be being installed. Likewise, masonry and steel fixing kits are potentially being used for timber stud structures - which if you have ever fire tested a shutter to BS EN 1634-1 is a catastrophic recipe for disaster. Manufacture and installation of fire shutters fall firmly within the remit of the new regulator as, they obviously fall under CPR 305/211 and are life safety products. The Door and Hardware Federation cite that “conforming to a hEN has legal consequences” and irrespective of BREXIT, hEN (Harmonised European Standards) apply. It follows that, fire shutter parameters must be set by an Extended Application (BS EN 15269-10) and no fire shutter can ever be installed into a flexible or timber stud structure if it does not have a separate fire test for such structures.

Compliant manufacturers will be able to demonstrate fire testing to multiple substrates within their Extended Applications.

Extract from A1S Group’s Extended Application to BSEN 15269-10 Evidencing Flexible AND Rigid Testing

The regulatory direction of travel for life critical products in the UK is clear, and the national complaints hotline will quickly and efficiently help expose breaches across the entire range of life safety construction products. Certainly, manufacturers and installers of life safety products will be under the microscope. Ignorance of CE marking and Construction Product Regulations will never be a defence, nor will obfuscation or confusion over any fixing structures and certification requirements under harmonised European Standards. Fines and retrospective costs could be crippling.

To reiterate, as a company, the A1S Group is accredited to manufacture fire shutters for BOTH flexible (timber stud) AND rigid (masonry and steel) structures. It is not our role to police manufacturer’s certification within our industry, but we are glad that there is a new sheriff in town.

For a simplified guide on the mandatory legislation and required certification from November 2019, please see: https://a1sgroup.com/blog/a1s-group-policy-when-quoting-ce-marked-fire-shutters

A1 Shutters Limited assume no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an "as is" basis with no guarantees of completeness, accuracy, usefulness or timeliness. Analysis of product properties and their suitability for any given application should always be undertaken and confirmed by competent professionals.